Looking Beyond Interconnect Standards

June 29, 2023

Blog

Respect for industry standards is central to the electronic engineering profession. Although this is valid, adhering to these standards can compromise engineers' design goals. One such area is the NewSpace industry, where the drive for smaller, lighter, and more affordable components are key criteria.

With the emergence of the private space industry, the dynamics have changed. Many new entrants are appearing alongside the prominent established players; many smaller ventures (both commercial and academic) are getting involved. Generally speaking, these enterprises will develop some form of nanosatellite or modestly-sized nanosatellite constellation.

In most of these cases, the design criteria that projects must respect are quite different from those of the traditional participants in this sector. Above all, having components that will keep designs as streamlined and cost-effective as possible will be crucial.

Suppose engineers look at the approved lists of space agencies. In that case, some of the connector formats cited may have remained static for years. They may also need to align better with the weight, size, and budgetary limitations associated with nanosatellite implementation. By specifying such components, it won't be feasible to fit all the required functionality into the available space. More importantly, the weight involved will likely exceed the rocket launch payload allocated to the project.

Admittedly, compliance with certain standards will be obligatory in some situations, such as government funding ventures. However, if this is not the case, engineers may prefer commercial-off-the-shelf (COTS) products that meet the high-reliability and performance criteria. For space launch conditions, a strong resilience to shock and vibration is vital. And, while in space, strong outgassing performance ensures that the connectors won’t degrade the surrounding equipment or, worse still, jeopardize performance. Following this route gives them more design flexibility, enabling them to address the engineering constraints of the application while keeping within budget.

It's not just the NewSpace industry where high-reliability COTS products are applicable; industrial, aerospace & defense, and electric vehicles (EVs) and the charging infrastructure are also candidates where rapid access to COTS connector models helps accelerate product development activities. It will also protect them from long lead times should supply channel shortages occur as it broadens the range of procurement choices.

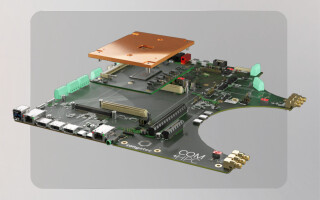

Harwin's philosophy towards connector design is fully focused on the needs of the engineer. As such, the company's HRi range of connectors has the high-reliability and performance attributes engineers need for their design while meeting the size, weight, power, and cost (SWAP-C) objectives. The compact and lightweight Gecko, high-density Datamate, and the high-power Kona series are all part of this high-reliability (Hi-Rel) interconnect portfolio. These connectors are resilient to shock and vibration, display strong outgassing properties, and are, therefore, fully aligned with the stringent directives set by both the NASA and ESA space agencies.

Leading Performance

For use within nanosatellites, among other places, the 1.25mm high-reliability Gecko connectors address acute needs to save board real estate and keep overall system weight down. In addition to its industry-leading performance and COTS availability, it makes them much more attuned to modern space endeavors. These connectors have exceptional resilience to mechanical stresses and can feature various locking mechanisms for mating retention. The operational temperature range, which spans from -65°C to +150°C, is also highly advantageous.

Figure 1: Gecko-MT connectors feature 10A power contacts next to 1.25mm pitch signal contacts

Gecko-MT versions, which combine combined data (2.8A) and power (10A) delivery, present engineers with an attractive alternative to the Combi-D/Micro-D format. By specifying these components, engineers will be able to streamline their designs further, improving size and weight profiles with less cabling. Because of the fewer components used, bill-of-materials costs are also reduced. Thanks to their lightweight and compact construction, these components may also apply to uncrewed aerial vehicles (UAVs) and drones.

Figure 2: Datamate Mix-Tek connectors are available in configurations of single-row power/coax contacts with double row signal contacts in one connector

Since its launch almost 40 years ago, Harwin’s Datamate has been the connector range of choice in many demanding applications and has a long track record in space. The connectors provide high resilience to shock and vibration and can withstand temperatures of up to +125°C. With small footprints, the SWaP-C optimized 2mm-pitch components fit into spaces other connectors in this class would struggle to accommodate. As with the Gecko range, the Datamate Mix-Tek versions carry data and power for an even smaller space envelope.

Figure 3: Kona delivers the ultimate power connector with 60A max per contact on an 8.5mm pitch.

With the recent introduction of the Kona series, Harwin significantly raised the power levels within its HRi range with each contact delivering 60A. The combination of high-power operation and strong reliability is unique for this size and format. Even though the 8.5mm contact pitch of these connectors is large, they take up relatively little board space as fewer contacts are needed to deliver the high current.

A Practical Approach to Connector Selection

In conclusion, it is clear that though standards should assist engineers in finding the best interconnect components for their designs, the reality is sometimes more complex than people might imagine. By taking a more pragmatic approach to connector choice, engineers can reap the benefits of having a high-reliability interconnect solution while meeting their SWAP-C targets and not being affected by supply chain hold-ups.