Hardware developers: Take a cue from your software brethren

December 20, 2016

Software developers have a great solution in the open-source world, where they can tap into code and libraries that give them a head start on the deve...

Software developers have a great solution in the open-source world, where they can tap into code and libraries that give them a head start on the development process. What a great way to save time and stand on the shoulders of giants! Since your life as an engineer is about doing more with less, why not take advantage of a similar resource? As a hardware designer, you could reap the kinds of timesaving benefits that your software brethren enjoy if you start your design process by first looking for a relevant reference design.

Some reference designs consist primarily of schematics. While having this sort of design blueprint is a useful, potentially timesaving guide, nothing beats a reference design that provides more of a full-fledged development platform. Say you’re developing a wearable fitness and health-monitoring device. You’ll probably want an easy way to test out more than one use case – from measuring heart rate to monitoring body temperature, blood-oxygen levels, etc. Or maybe you’re creating a smart home security camera and need to make sure that the system will be safe from hackers.

Using the right reference design can save substantial time in each of the steps that you and your project team members must complete to turn your ideas into working products:

- Evaluating components from different vendors, assessing factors such as performance, power consumption, pricing, and availability

- Ordering the parts and waiting for delivery

- Building a working prototype and evaluating its functionality, potential problems, and the like. Are there critical design flaws, or simply issues in the prototype itself?

- Fabricating near-final PCB prototypes and moving on to final system integration, debug, and other last steps

Shave time off your development cycle

While tools such as emulators can support early software development, actual silicon is needed for you to perform many development and integration tasks. Going back to our wearable healthcare device example, this is the type of product that needs to interface with multiple types of analog sensors. Each sensor would have a different signal interface level, type, and noise issues.

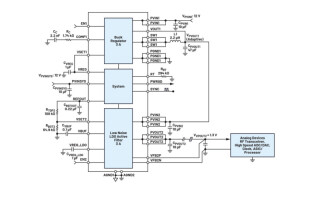

A reference design can help shorten the prototype development cycle by up to six months while also enabling you to quickly evaluate the effectiveness of various health sensor solutions such as optical, electrocardiogram (ECG), temperature, and multi-sensor solutions (Figure 1).

[Figure 1 | Maxim’s hSensor Platform, measuring 25.4mm x 30.5mm, is supported on the ARM mbed IoT Device Platform, which allows further optimization for specific use cases.]

With a good reference design in hand, you won’t need to start from scratch when you’re ready to embark on a new design. After all, today’s ICs are system-level components that call for expertise in a broad range of areas like analog and digital design, power-supply requirements, and board layout, to name a few. Using a reference design as a starting point lets you focus on product differentiation. Just look for designs that include more than a schematic — Gerber files, models, test data, drivers, and development tools, for example. After ordering, you should have your board in a few days and you can start testing, which beats the few weeks it could take to build your own prototyping board. Considering all of the time and effort that reference designs can save, it’s a wonder why more hardware designers aren’t turning to them before they start working on their projects.