PICMG ModBlox7™: An Open, Flexible Standard for the Growing Industrial Box PC Market

September 20, 2022

Story

Industrial box PCs are some of the most common electronic systems in the world. In virtually every harsh environment or heavy industry use case that leverages electronics, chances are you’ll find an industrial box PC nearby. And their popularity is growing, as DIN rail mount box IPCs are becoming the solution of choice for companies looking to extend enterprise networks into connected factory and manufacturing environments.

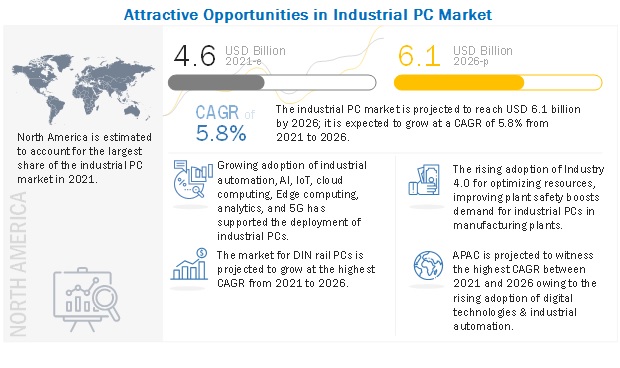

Figure 1. The Industrial PC market is projected to grow to more than $6.1 billion in the next five years on the strength of DIN rail mount Industrial Box PCs. (Source: MarketsandMarkets)

An industrial box PC, or box IPC, is a type of compact, fanless industrial computer that’s typically compact and designed to the specific requirements of the target application. Its performance, I/O, thermal management, housing, and even form factor can all be customized before the final product is manufactured at low- to moderate volumes. One way to deploy them is on a DIN rail, which allows one or more box IPCs to be mounted in a rack/cabinet or on a wall, presumably in close proximity to a data acquisition or control system they manage.

Placing their hallmark versatility to the side, it’s surprising no industry standards exist for box IPCs given the sheer demand for the technology. Doing so would lower costs for both equipment manufacturers and end users. And, if architected correctly, a standard could meet the needs of multiple market segments while allowing hardware to be modified according to a specific use case.

Recognizing this market need, 15 member companies of the PCI Industrial Computer Manufacturers Group (PICMG) recently embarked on a standardization effort to create an open industrial box PC specification that checks all the above boxes.

The goal of that work is the ModBlox7™ open, modular industrial box PC industry standard.

Figure 2. ModBlox7 will be the industry’s first open industrial box PC specification.

Introducing ModBlox7

Scheduled for ratification in Q1 2023, the ModBlox7 specification gets its name from the ability to mix-and-match fixed-height, fixed-depth “blocks” that are each 7HP wide. ModBlox7 defines three types of units – a CPU Unit, a Power Supply Unit, and I/O Units – that connect via standard internal PCIe Gen 2, 3, 4, or USB interfaces in chains of up to 12 total blocks that form open, high-performance industrial box PCs.

The draft specification calls for each individual unit to contain a front plate and space for internal conduction cooling, as well as power and data connectors. Presently, these are represented by:

- An 8-pin, 2.00 mm Samtec UMP(C)X (or compatible) rugged power connector

- An ept GmbH Zero8 405/6-51080-51 (or compatible) angled board-to-board connector capable of transmitting USB and PCIe signals at data rates up to 16 Gbps

Having these robust COTS connectors on every ModBlox7 block eliminates the need for a traditional backplane but allows the CPU and Power Supply Units to link to as many as four PCIe-based I/O blocks or up to eight USB I/O blocks. Redundant configurations are also supported for safety or reliability use cases.

Figure 3. ModBlox7 industrial box PC systems comprise CPU, PSU, and I/O Units connected via COTS power and board-to-board PCB connectors that transmit PCIe or USB data signals. Redundant architectures are also supported.

Figure 4. An 8-pin, 2.00 mm Samtec UMP(C)X (or compatible) connector has been proposed as the internal power transport mechanism for ModBlox7 blocks, while ept GmbH Zero8 405/6-51080-51 board-to-board (or compatible) connectors are a promising data transport interface given the vibration, speed, temperature, and mating requirements of various IPC industries.

Beyond what’s described in the specification, ModBlox I/O Units can be customized to the application-specific connectivity requirements of transportation, automation, military, medical, and other vertical markets. For example, analog, digital, or serial I/Os; LTE or Wi-Fi interfaces; an MVBus for connecting to the backbone of a train; and more can all be brought out through the I/O Unit front plates.

And because the proposed standard is open and modular, this application-specific functionality can be added, removed, or swapped out later by simply plugging it in.

Standardizing Custom Industrial Box PCs Through an Open Approach

The wide range of use cases PICMG members hope to support with ModBlox7 technology makes openness key to the specification’s viability. From a CPU perspective, this is realized through processor agnosticism that’s limited only by the power and thermal profile of the host CPU and its support for PCIe and USB interfaces.

This low barrier means thousands of Arm, x86, and other embedded processors and microcontrollers can be adopted to help OEMs swing a ModBlox7 system towards higher performance or lower cost. Because PCIe and USB interfaces come standard on the vast majority of embedded processors, specialized drivers or software support will not be required in most cases.

While the choice of processor will determine the power consumption of the CPU Unit, the maximum power defined for I/O modules is 75W. To ensure heat generated by the system is sufficiently dissipated, the ModBlox7 specification plans to allocate space for passive thermal management technology in the form of an optional heatsink within each block. Though the specification will not define an explicit thermal management technology at present, provisioning for one ensures electromechanical compatibility across ModBlox7-compliant blocks and box PCs.

Figure 5. The ModBlox7 specification defines space for an optional heatsink.

Likewise, an enclosure has been outlined to help maintain mechanical consistency between CPU, PSU, and I/O Units. However, the primary focus of the enclosure is to reserve space for the internal ModBlox7 block components and guarantee robust physical mating of connectors. Currently, the specification calls for from an enclosure is two side walls, a front panel that doesn’t identify external connectors, and something like an extruded U-profile housing.

Figure 6. The ModBlox7 specification defines a very open mechanical enclosure that streamlines sourcing while leaving room for customization.

In fact, the draft specification doesn’t define adapters for the possible ModBlox7 mounting options either, just that it can be mounted. This means future ModBlox7 users will be able to order a standard enclosure that slots into a 3U rackmount system from a catalog vendor, or source their own custom housing that can easily be made compliant to the standard.

In terms of configuration and mounting options, all that’s required of a ModBlox7 system right now is the presence of a CPU and Power Supply Unit (which can be collocated in the same block) since a CPU block will inherently contain some I/O of its own. As mentioned, these can be combined with various I/O block configurations to extend a ModBlox7 industrial box PC to include as many as 12 daisy-chained blocks in runs up to 84HP long.

Upon deployment, ModBlox7 blocks will be able to be mounted on a wall, 19" rack, or DIN rail according to the operational environment. Because of the monolithic housing described previously, changing the mounting configuration doesn’t impact the box design itself, just the mounting mechanics.

Figure 7. ModBlox7 industrial box PCs can be mounted on a wall, DIN rail, or withing 19" racks or cabinets.

Scaling Industrial Computing Through Standards

With the industrial PC market already valued at more than $4.5 billion USD, the need for scalability is obvious. However, the success of industrial box PCs to date has been predicated on the ability of manufacturers to tailor solutions to their customers’ exact needs – a fact that can’t be lost in any standardization effort.

ModBlox7 will bring an elegant blend of definition and openness to this challenge by emphasizing simplicity, interoperability and extensibility in a specification that permits stakeholders to take or leave functionality as they see fit. Its modular architecture will allow systems integrators to optimize and differentiate industrial box PC solutions through their choice of CPU, by scaling or limiting the number of I/O Units, in modifying the enclosure, and more.

In other words, the first-ever industrial box PC standard projects to fill the same needs as hardware standards that have come before it: commoditize non-value add components of the design, create opportunities for vendors to enrich systems on top of those commodity frameworks, and lower cost and increase choice for the end user.

By doing so, PICMG ModBlox7 is poised to accelerate the transportation, industrial automation, military, medical, and other markets who stand to benefit from increased communications, control, and intelligence in places where an industrial box PC may be the only option.

PICMG member organizations currently participating in the ModBlox7 specification include Ci4Rail, EKF Elektronik GmbH, Elma Electronic, ELTEC Elektronik AG, Embeck Co., Ltd., ept GmbH, HEITEC AG, Hirose Electric Co., Ltd., PHOENIX CONTACT, Samtec, Sealevel Systems, Inc., TEWS TECHNOLOGIES GmbH, and others.

For more information, visit picmg.org/ModBlox7 or check out the infographic below.

RESOURCES:

- ept GmbH, D.-86971 P. (n.d.). Zero8 socket angled unshielded part no. 406-51080-51. ept. Retrieved September 19, 2022, from https://www.eptusa.com/index.php?406-51080-51_en

- Industrial PC Market. MarketsandMarkets Research. (n.d.). Retrieved September 19, 2022, from https://www.marketsandmarkets.com/Market-Reports/industrial-pc-market-169907425.html?gclid=CjwKCAjwg5uZBhATEiwAhhRLHnE9_bKHMqIgovkgq2PHdUqlJEYvuyhF_YtxHlShCgfkWt7hY1HT3hoCtbcQAvD_BwE.

- ModBlox7. PICMG. (2022, February 17). Retrieved September 19, 2022, from https://www.picmg.org/modblox7.

- PICMG Committee Designs New Modular Box PC Open Specification. Embedded Computing Design. Retrieved September 19, 2022, from https://embeddedcomputing.com/technology/open-source/board-system-standards/picmg-committee-designs-new-modular-box-pc-open-specification.

- UMPC. Samtec. (n.d.). Retrieved September 19, 2022, from https://www.samtec.com/products/umpc.