Standardized ARM Modules: The Affordable Way for GUI Designs

December 16, 2019

Blog

Do you remember the days when we used mechanical buttons, slide controllers, rotary switches and analogue display units to control and monitor machines? Yes.

Do you remember the days when we used mechanical buttons, slide controllers, rotary switches and analogue display units to control and monitor machines? Yes. Even today we find such controls in new products, but exceedingly less often. OEMs increasingly substitute them with GUIs. Benefits include higher software reuse, simplified mechanical designs, less components and, of course, better user experience – as long as the GUI is programmed to be understood intuitively and easily.

GUIs Replace Mechanical Buttons

This has become possible as both power consumption and costs for such solutions are declining. The same is true for the latest display technologies. Today, it is possible to offer attractive graphics at a TDP of only 1 to 2 watt for the processor and its embedded 3D GPU. Several years ago, the same graphic required 10 to 20 watt. Prices follow a similar trend. Both improvements now enable us to empower electromechanical controlled devices with colorful and intuitive 3D GUIs –at competitive prices. Not only have prices and power consumption decreased; today, more intelligence is built in as well. Think about voice control as an add-on. Think about vision and artificial intelligence (AI) to identify users or gestures. All this forms the backdrop in which the new NXP i.MX 8M Nano application processors enable us to give devices an interactive screen, where this was previously simply too expensive.

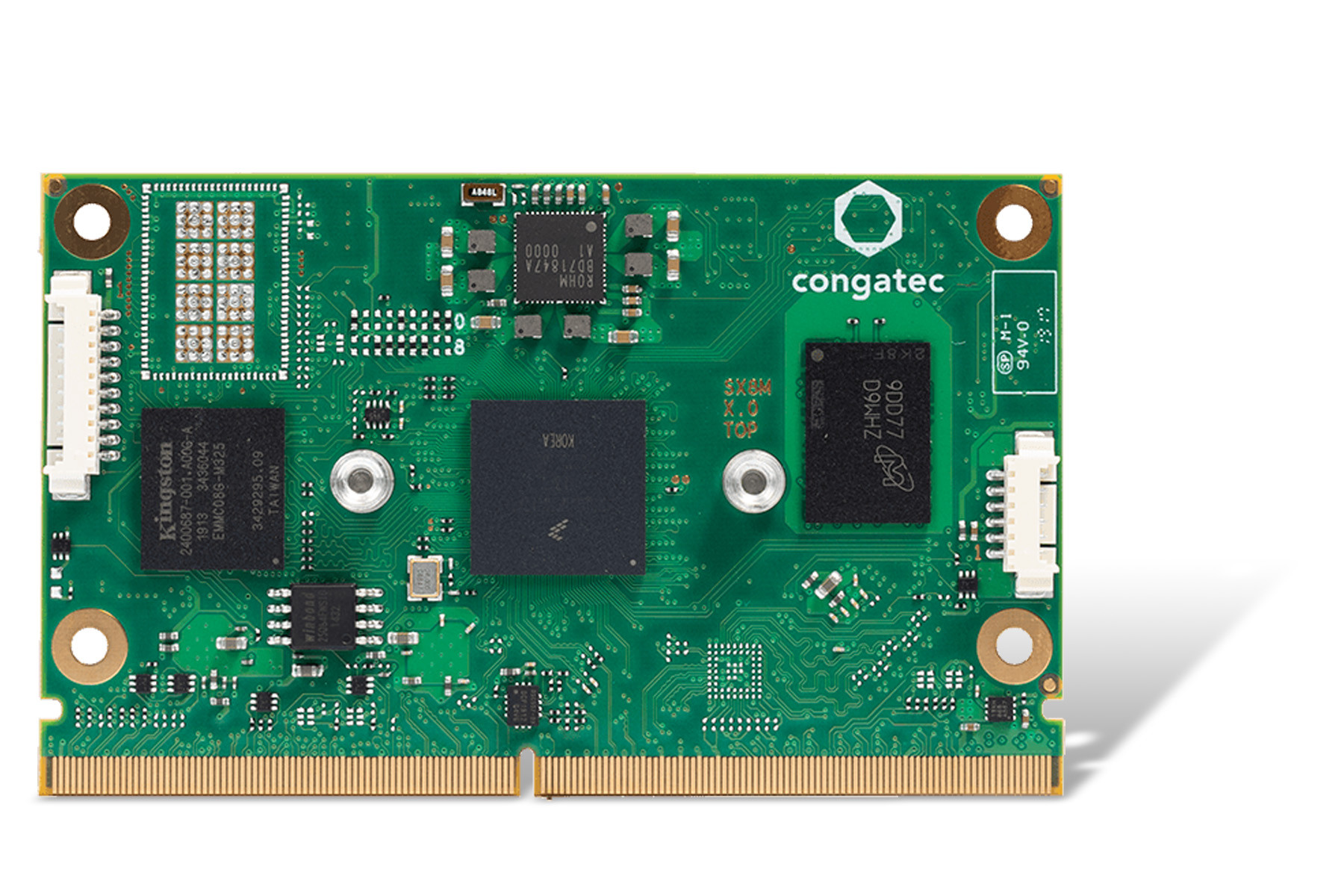

In mass series production, a custom specific design is often the best choice. Still, it is important to take into account that NRE costs are high for new designs needing to be developed from scratch. That is why more and more ARM engineers are starting to consider what is highly successful in the x86 business: standardized SMARC Computer-on-Modules. By utilizing the extensive SMARC ecosystem, engineers benefit from far more advanced and ready to use components, standardized APIs and comprehensive BSPs. Another major plus is the tremendous scalability, reaching way beyond the pin compatibility of certain application processor variants.

Less NRE Costs, Faster Time-to-Market

Application readiness and scalability are the two major reasons for engineers to switch over to ARM based Computer-on-Modules. They want to come to market quickly, save NRE costs, and optimally balance the price and performance ratio for their product families. With SMARC, the embedded computing industry offers all these benefits off-the-shelf. At present, engineers can scale application-ready platforms within the entire i.MX 8M portfolio as well as beyond, continuing towards various low-power application processors. This hardware-agnostic benefit, with its inherent long-term availability and closed loop engineering capability, is another major reason why ARM application processor engineers increasingly rely on the proven design principles of standardized Computer-on-Modules.

Application Readiness is Key

Thanks to the brand new NXP i.MX 8M Nano processor, SMARC modules have now reached a new milestone for the class of ultra-low power 3D GUIs, which previously was only possible at higher prices and with a higher TDP. Both addressing new application areas and substituting more expensive or power intensive GUIs is quite cost and time efficient with SMARC modules. These application-ready subsystems come with a comprehensive ecosystem, including a ready-to-go boot loader implementation, pre-qualified Linux, Yocto and Android BSPs. And they offer fully featured evaluation carrier boards that significantly simplify the integration of the new ARM based NXP processor for customers. This even includes the option to fuse modules and carrier boards once mass series production is about to start. If you are unsure about the extent to which standardized SMARC Computer-on-Modules will pay off for you, manufacturers will be happy to provide you with a customized ROI calculation.