Want USB-C? Do it right!

October 11, 2017

USB-C is capable of delivering all USB performance levels ? from 12 Mbps with USB 1.0 up to 10 Gbps with USB 3.1 Gen 2 ? via a new symmetrical connector that is reversible.

USB is a universally applicable interface standard that is widely accepted. Embedded computing engineers even use it for internal extensions, as it is a convenient and less complex interface than a generic PCIe extension. USB-C is the latest enhancement of this plug and play standard published by the USB Implementers Forum (USB-IF). What are the advantages of this new specification and which pitfalls should embedded system engineers avoid?

USB-C is capable of delivering all USB performance levels – from 12 Mbps with USB 1.0 up to 10 Gbps with USB 3.1 Gen 2 – via a new symmetrical connector that is reversible, relieving the user of the annoying "try, twist, and retry" approach of USB-A, USB Mini and micro USB connectors. The new USB-C standard offers more signal lanes to provide far more plug and play functionality. You can use USB-C to drive an all-in-one touch display as well as a high capacity power supply, powering or charging devices with up to 5 A current at 20 VDC and 100 W – with one cable, and in both directions, as source or sink.

The increased multi-functionality of USB-C for display connectivity and power support is attractive for space constrained systems such as mobile phones, tablets and notebooks. That’s why these markets are adopting USB-C fast with a CAGR of approx. 70% within 2016 and 2021 as ABI research predicts. The broad acceptance of the consumer market makes USB-C also attractive for embedded devices such as rugged portable handhelds. The use case here is more or less the same: To use a single connector for various purposes, thereby reducing costs and making space for as many interfaces as possible. The consolidation of interfaces to a single connector type is also beneficial for many other embedded applications and for all parties involved – from embedded board and system designers up to system integrators and industrial end users. Future embedded systems could one day look similar to what we know from Ethernet switches and would be just as easy and simple to use with only one interface type in scalable configuration for all purposes.

Early adopters should definitely have a look at the pitfalls that might lurk on your path to a successful USB-C implementation as we have seen many of them:

- USB-C cables can be plugged into the end devices in two orientations, but independent tests showed that certain cable and device combinations only work properly, when the cable was plugged in a specific orientation. Verify that cables are fully fledged and in accordance with the specification.

- With USB-C Power Delivery (PD) new power limits are allowed up to 100 Watts via a programmable controller. The available components differ in functionality and programmability. Look for embedded vendors that offer evaluated designs and are willing to share their expertise and re-use their best practice.

- The most interesting alternate modes for embedded applications are the DisplayPort or HDMI modes. We recommend the DP-mode, because it offers increased bandwidth even for daisy chaining, HDR10 and up to 32 audio channels.

- Alternate modes and current ratings above 3 A require electronically marked cables. In that case you mustn’t use a passive cable. Ideally deliver evaluated and tested USB-C cables with your designs.

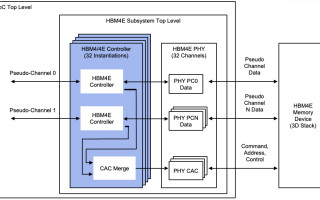

If you are wondering whether USB-C is suitable for rugged applications, you should remember what industries have done in the past: USB has been made available in various connectivity formats, from internal and external standard plugs and connectors to MIL specified M12 connectors. Hence, fully rugged connectivity options can be made available for the 24-pin-based USB-C as well. So, think about your demands in terms of USB-C connectivity and play a little with the options to move existing interfaces towards USB-C. Suitable embedded platforms already exist. For individual implementation some vendors even may deliver their USB-C circuit diagrams, so you have a perfectly elaborated blueprint. Take a look for example at our conga-SEVAL SMARC carrier board. It already has one USB –C port. For applications that are perfectly served with a standard board, the Pico-ITX conga-PA5 might suit as well.

[Figure 1 | The blue prints of the congatec SMARC carrier board schematics with USB-C connectivity are free for starter kit customers.]