From Reactive to Predictive: Revolutionizing Industrial Maintenance with Cervoz

October 09, 2024

Sponsored Blog

In industrial automation, maintaining machine and process health is as crucial as the automation itself, evolving from a reactive approach to a more sophisticated, data-driven strategy. Initially, reactive maintenance fixed issues only after they caused costly downtimes and production delays. Preventive maintenance marked the next step, introducing regular inspections and part replacements to reduce such risks, but it still couldn't fully optimize asset utilization. Predictive Maintenance (PdM) now represents the pinnacle of this evolution in asset management, harnessing data, artificial intelligence (AI), and advanced hardware to anticipate and resolve potential issues before they escalate into failures, thus ensuring peak equipment performance and seamless operations.

What is Predictive Maintenance?

Predictive Maintenance (PdM) is a proactive method that leverages real-time data from sensors and performance metrics to foresee and prevent equipment failures. Continuous monitoring of factors like temperature, vibration, and lubrication provides data that advanced algorithms and machine learning models analyze to detect patterns indicating deterioration or potential breakdowns. These insights help maintenance teams optimize schedules, target interventions, reduce disruptions, and extend equipment lifespan.

The Advantages of Predictive Maintenance

Recognizing that different projects have unique requirements, PdM revolutionizes industrial operations by leveraging data analytics and machine learning. This proactive approach offers several key benefits:

Less Downtime

- PdM minimizes unexpected failures and associated downtimes through proactive alerts and regular maintenance scheduling.

Better Asset Life

- Continuous monitoring and timely maintenance enhance asset performance and extend equipment lifespan.

Lower Costs

- By predicting potential failures and monitoring key indicators, PdM optimizes resources, stabilizes operations, and reduces unnecessary maintenance expenses.

Higher Productivity

- With reduced maintenance time and minimized costly downtimes, PdM streamlines scheduling and boosts overall productivity.

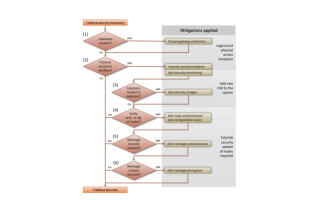

Challenges in Implementing PdM

Predictive maintenance is revolutionizing industries globally, from manufacturing, energy, and transportation. In the context of Industry 4.0, it is crucial for smart factories, enabling seamless operations, quality control, and cost optimization. While predictive maintenance offers substantial benefits, its implementation is not without challenges:

- Real-time collection, storage, and analysis of large, complex sensor data.

- Fast retrieval and mining of extensive historical data for accurate insights.

- High-precision models and algorithms for reliable failure prediction.

- A responsive, reliable, and scalable system for dynamic industrial environments.

Achieving effective predictive maintenance requires robust data handling, swift analysis, precise prediction models, and a system that adapts seamlessly to dynamic industrial demands.

Maximize PdM Efficiency with Cervoz Industrial Solutions

Cervoz is committed to enhancing predictive maintenance systems with its industrial-grade modules that deliver reliability and performance. With high-capacity storage designed to handle extensive data streams, rapid-write speeds, and robust endurance, Cervoz ensures smooth data handling and long-term stability for predictive maintenance applications. Complemented by Cervoz’s DRAM modules featuring ECC for fast caching and reliable AI/ML data analysis, these solutions enable precise failure predictions and minimize downtime.

Cervoz also addresses the need for high-speed and reliable data communication with versatile expansion cards, such as 10GbE Ethernet and Wi-Fi 6E solutions, providing low-latency, high-bandwidth transfers that keep operations responsive and scalable. Every component is rigorously tested to withstand extreme temperatures, shock, vibration, and power fluctuations, ensuring consistent performance even in harsh industrial environments.

Achieve Peak Performance in Smart Manufacturing

Integrating Cervoz’s advanced storage, memory, and expansion solutions boosts equipment reliability, optimizes maintenance, and reduces costs, creating a strong foundation for efficient predictive maintenance in smart manufacturing. Achieve manufacturing excellence with Cervoz's innovative, data-driven approach. Contact Cervoz to develop a future-ready strategy.