Limata's LUVIR Technology Speeds Up PCB Solder Mask Production

August 13, 2020

News

LUVIR delivers imaging speed and throughput on all solder mask ink types at lower cost-per-print.

Limata announced the availability of its proprietary and field-proven LUVIR Technology on all X-series model types. The LDI technology is designed to increase the speed of solder mask (SM) direct imaging at lower Total Cost of Ownership (TCO).

Limata has developed a new approach for solder mask exposure, that utilizes both, UV- and infrared (IR-) lasers. According to the company, this combined laser approach shortens imaging cycle times and increases throughput (prints or panels per hour) further delivering contamination ('bleeding') values on all conventional ink types.

"With LUVIR, we are able to deliver the same imaging results at lower UV-laser energy levels of just 100 to 250mJ/cm2 compared with 400 to 1,000mJ/cm2 required on LED/DMD systems - with no compromises on surface quality, resolution or accuracy," said Matthias Nagel, CTO of Limata. "Using IR enables us to downsize the UV-laser capacity in our systems, which supports lower equipment costs, ultimately delivering the best price/performance value of any DI solder mask system currently available in the market."

Higher imaging efficiency and throughput levels with LUVIR are on all conventional solder mask ink types and colors (green, blue and black) as well as on legend inks (white), further eliminating the need for PCB manufacturers to transition from conventional standard ink material to more expensive DI inks. In addition, LUVIR fully supports the digital imaging of PCB structures at coating thicknesses in the 4 mil (100 µm) to 6 mil (150 µm) range without undercut. This is a direct imaging task that cannot be processed by multi-wavelength DMD/LED systems at reasonable speed levels or yields.

Also, according to the company, PCB production data from the field have proven imaging and throughput advantages with LUVIR on all conventional solder masks, with inks at up to 40% lower costs per print compared to DI system peers.

The use of long-lifetime components for its UV/IR imaging module complemented by an in-house developed sensor array for the automatic remote calibration of lasers reduces maintenance requirements and after-sales costs by further eliminating the need for manufacturers to enter into expensive long-term service agreements over the equipment lifecycle.

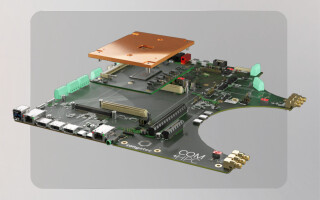

LIMATA's X2000-series platform, powered by LUVIR in a four UV/IR imaging head configuration, supports high-volume PCB capacity requirements. The availability of LUVIR on a more compact system platform (X1000) lowers the entry barriers for quick-turn-around manufacturers considering transitioning from mask/film and investing in a digital system solution for solder mask direct imaging.

LIMATA was recently acknowledged for its LUVIR innovation with the Productronica Innovation Award 2019 in the PCB & EMS Cluster. The technology is available on all LIMATA X-series system models featuring a range of options addressing individual PCB customer needs in different markets and regions. All X-Series systems also support the direct-imaging of dry-film (photoresist) down to a resolution of 1 mil (25 µm) line and space.

For more information, visit www.limata.com