Consumerization hits industrial

September 19, 2018

Blog

In the industrial sector, users who have become accustomed to fast-changing trends in the consumer area now expect the same to apply in their own marketplace.

Whatever the area concerned, the pace of life is speeding up. That’s certainly applicable in the industrial sector, where users who have become accustomed to fast-changing trends in the consumer area now expect the same to apply in their own marketplace. They’re beguiled by the world of frequent launches of new mobile handsets with increasingly whizzy features, of Bluetooth products, touch screens and rapid advances in sensors. No longer is industrial a haven of tranquillity, where the pace of change is slow and there is plenty of time available for testing products designed to operate flawlessly in demanding and rugged environments.

Despite the accelerated pace, users still expect their products to be well tested and to maintain their high standard of production. They also want to incorporate as many as possible of those features borrowed from consumer technology. With high quality expected to be a byword, it’s important that products come up to standard by conforming to industry standards such as ISO 9001 for quality management.

Industry 4.0

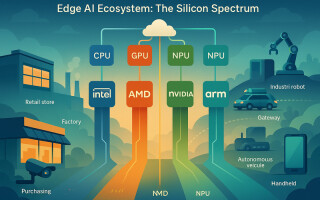

Industrial change has become one of the key challenges of the 21st century, keeping pace with economic and social development and incorporating features derived from the digital revolution as well as from the changing shape of the energy market and from galloping globalization. Initiatives such as Industry 4.0 (basically the digitization of the manufacturing industry) and rapid developments in the area of artificial intelligence all contribute to the demands being placed on the industry.

Designers of industrial products really have to have their wits about them. They need to be sharp, on the ball and able to assimilate rapidly which of the latest trends are most suitable for incorporation into their products – and then implement them.

As the European Economic and Social Committee says, “both traditional sectors – such as heavy manufacturing – and emerging sectors in greener and knowledge-based industries will need to develop a proactive approach, anticipating, adapting to and managing change with new sustainable technologies and new jobs and re-skilling to match the challenges of Industry 4.0.”

Impacts on Industrial Products

The Internet of Things (IoT) is having a dramatic impact on industrial technology, as it is on most areas of life. One of the major effects on the designers of industrial products is that they are faced with tackling issues to do with pricing. Users accustomed to competitive pricing in the consumer sector because of the high volumes found there are now expecting the same conditions to apply in the industrial arena. Given that Industrial IoT (IIoT) products may contain hundreds or even thousands of individual components, that can put considerable pressure on pricing for the designer to satisfy.

It may well be that the answer to cost-based issues is to be found in a custom application-specific integrated circuit (ASIC) rather than expecting to be able to satisfy requirements using an off-the-shelf product. The demanding requirements often associated with industrial products may also make this a wise choice. For instance, rugged industrial products are likely to use proprietary Ethernet protocols for networking rather than the TCP/IP more commonly employed by consumer products.

Low latency is a vital requirement of many industrial products; consumer products are nowhere near as demanding in terms of their connection requirements. A few packets dropped in transmission are of little account when the data being transmitted is between high-tech gadgets. For an industrial device or system, accurate and timely transmission of data is vital to ensure that the entire system keeps on running smoothly, with no interruptions.

One good example of where a custom device can outperform a standard product offering is in an application such as an IIoT real-time control system. System sensors gather data that need to be processed locally and in a highly responsive and secure fashion. This can be a hard requirement to satisfy for a standard device, but a system such as the SmartEdge platform from S3 Semiconductors can combine all of the required functionality in a single custom mixed-signal ASIC. A typical device – if there is such a thing – could include an analog front end (AFE) coupled with calibration, control, communication and security functionality.

While the device might fit the bill, it’s also important not to forget that you need good back-up service from the vendor. Check that the supplier really knows what they are talking about and can show you strength in terms of application expertise as well as having a strong stable of embedded software.

Choosing the right horse for the course is definitely your best bet. It’s instrumental to remember that the bookmakers will always come out on top!

Edel Griffith is the Technical Marketing Manager at S3 Semiconductors, a Division of Adesto. She has over 20 years of experience in the semiconductor industry in both R&D and technical marketing roles. She has a degree in Applied Physics and Electronics from the National University of Ireland, Galway and an Executive Diploma in Strategic Digital Marketing from Dublin Institute of Technology, Ireland.