Assembling the Pieces of the AIoT Puzzle

June 01, 2021

Blog

Note: This is the fourth in a series of four blogs (and associated podcasts). First, I looked at what it means to be operating an AIoT platform. In the second, I went through some of the subsystems that go into that AIoT platform, drilling down into the nuts and bolts. The third covered AMRs.

A phrase that’s becoming more common in American vernacular is “the juice is worth the squeeze.” It means that the reward is worth the effort. In this case, the “reward” is an AI platform that operates at the edge of the IoT, or potentially an automated mobile robot (AMR). If designed properly, the benefits of these systems are immense, and certainly worth the design effort.

The necessary pieces required to build such an AIoT system include:

- how you acquire the analog data from the real world;

- how you digitize those signals or, more likely, images;

- the analytics;

- converting all of those parts into logical, safe, and reliable actions.

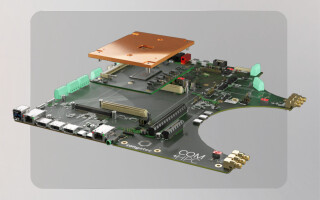

Obviously, the operation requires incremental and iterative processing, which is generally executed in some combination of CPU, GPU, FPGA, and/or VPU. In many cases, we start by interfacing with image sensors, then acquire and process images in real time. The images are transcoded and the information is sent to a compute engine, which analyzes the data for actionable insights.

Putting all of these complex processes together, including sensing, computing, actuating, and so on, typically requires input from various third parties, often referred to as the hardware and software ecosystem. According to Zane Tsai, the Director of ADLINK Technology’s Platform Product Center, “No single company can handle all the requirements in this process. So the ecosystem is vital to put these technologies together, as they all have different specialties. And the most important part is how we glue them all together into a single system.”

Take the AMR, for example, as it is gaining wider acceptance in industrial and automation applications. It’s a relatively large system that’s composed of many smaller, disparate systems, both in terms of hardware and software. There’s typically lots of sensor interaction that’s required. The sensors, which generate a huge volume of data in different formats, likely come from different manufacturers with different interfaces. This concept is sometimes referred to as sensor fusion.

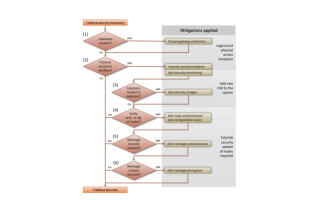

The developer would have to dig deep into the partner ecosystem of hardware, software, and firmware to ensure that all data is transcoded, transmitted, and inferenced in real time so the AMR can move safely without human intervention. Machines working autonomously at the edge give rise to close, sophisticated communication and collaboration, resulting in enhanced operation and production.

The 5G Super Highway

One potentially important “component” is the 5G network that can wirelessly “connect” all the pieces. 5G is the catalyst for fast and reliable connections in AMRs and other AIoT platforms that truly live at the edge of the IoT. 5G brings a significant capacity enhancement with enhanced mobile broadband (eMBB). And it features ultra-reliable, low-latency communication (URLLC), which is needed to stream much higher resolution video. At the same time, 5G offers a connection to a large number of devices with massive machine-type communications (mMTC). Many OEMs would not even attempt an application like this without 5G and the security and reliability that comes with it.

To hear more in-depth conversation about what’s required to assemble the various components of the AIoT system, including the vast partner ecosystem, check out the podcast here, which features ADLINK Technology’s Zane Tsai.