How to Improve Production Line Quality using Machine Learning at the Edge

May 03, 2022

Story

The industry 4.0 paradigm encourages the manufacturing industry to use machine learning, artificial intelligence, cloud computing, and industrial internet of things (IIoT) technologies to improve industrial process, product quality, and reduce cost and time to market.

Machine learning algorithms act as an intelligent decision support system for OEMs and is applicable to variety of manufacturing applications such as:

- Predictive maintenance

- Product quality control improvement

- Machine anomaly detection

- Production line monitoring

- Supply chain management, etc.

Smart factories and warehouses continuously collect and share massive data through connected devices and distributed infrastructure. Analyzing enormous volumes of data using complex machine learning algorithms requires significant computational capabilities. Existing on-premises and centralized cloud infrastructure are capable but they have their own limitations in terms of latency, huge bandwidth consumption, security related issues etc. Some of the smart industrial applications require low latency to get real-time access to data. To reduce latency and bandwidth use, Machine Learning on the Edge is the solution.

The Bigger Picture: Machine Learning at the Edge in Smart Factories

Machine Learning at the Edge is a technique that enables data processing at the device level or local infrastructure at the “edge” of the network using machine learning or deep learning algorithms, reducing dependency on cloud networks. Edge computing allows for running computationally intensive machine learning algorithms on the edge. This helps to generate more real-time analytics and as a result, various types of applications are now possible for various industries.

In most cases, the Machine Learning model is programmed in frameworks like Tensorflow, Keras, Caffe etc. Using these frameworks, the programmed model is trained on high end platforms like a computer system (PC or Laptop), or cloud platforms like Microsoft Azure, Google cloud, Amazon AWS, etc. Once the model is trained, it is saved and deployed on the cloud platforms, or more relevant embedded platforms for real-time inference (predictions), like NXP IMX8M based devices.

AI/ML, and especially ML at the Edge, has become an important technology to drive the growth of Industry 4.0. It is playing a very important role to improve the quality of the product in the smart factories.

Applications of Machine Learning Models for Various Manufacturing Operations

- Surface inspection: For electronics manufacturing, surface inspection includes solder joint inspection, completeness check, connector pin inspection, cosmetic housing inspection, etc.

- Texture inspection: In different types of objects, their quality is reflected in their surface texture. So, vision-based texture inspection plays an important role in deciding the quality of the object. In plywood manufacturing wood is the raw material. The presence of a knot in the wood weakens the lumber and increases the possibility of fracture. This weakness depends on its size, position, number, and condition. Using a Deep learning-based vision model, presence of the knot in the wood can be detected, counted, and size can be measured.

- Defect detection: There are numerous examples where vision-based algorithms can be useful to detect defects in the product. For example, in pharmaceutical manufacturing vision-based models can help to detect various defects i.e., color deviation, dent or holes in the capsules, irregular shapes or damaged edges or the cracks of the pills, etc. It can identify foreign objects in the production line.

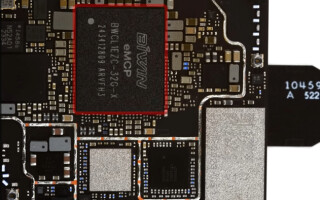

With the advancement of semiconductor technology, it is possible to deploy these computationally heavy algorithms on the edge platform. With the integration of Graphics Processing Units, Digital Signal Processing, Neural Processing Unit in the various SoCs it is possible to achieve real-time performance on low power, low cost platforms.

How to Ensure Quality of Manufactured Products in the Smart Factories?

Some of the key factors that play a very important role in maintaining the quality of the product manufactured in the smart factories are:

-

Consistent Operations of Machines

For the consistent quality of the manufactured product, it is important that all the machines operate in their best condition with maximum efficiency and minimum downtime. Machine Learning-based predictive maintenance uses various techniques like anomaly detection for early identification of the machine failure and its timely maintenance. Various physical parameters i.e., vibrations, noise, temperature, electricity consumption, etc. are monitored and based on their anomalous behavior maintenance can be predicted.

For manufacturers, predictive maintenance is a gamechanger. It helps them take a data-driven decision for smart manufacturing. With the help of various low-cost, low-power MCUs, this can be deployed in the factory in a very cost-effective way. The sensors generate a huge amount of data for various physical properties, and it is not practical to send all this raw data to the cloud for ML use cases. It is very important to leverage the processing capability of edge devices.

- In-Process Quality Control

In the traditional manufacturing process, visual inspection and quality control related activities are taken care of by humans. Manual inspection of product quality can be inaccurate. This results in defective products, lack of compliance, and loss of revenue. To overcome this issue, vision-based deep learning models are used in smart factories.

Classification of the vision-based deep learning models are as mentioned below:

- Image Classification: Identifying the presence of the object in the image, i.e., wood, medicine, fruits/vegetables, etc.

- Object Localization: Here along with identifying the object, a bounding box is determined to locate the exact location of the object in the image.

- Semantic Segmentation: This refers to the linking of each pixel of the image to a particular class label.

- Instance Segmentation: It is very similar to semantic segmentation, but it treats multiple objects of the same class.

Machine learning models are poised to transform the manufacturing industry, using image classification for monitoring machine wear-and-tear on the assembly line, to performing quality inspections of work-in-progress and finished products.

Kaumil Desai is associated with VOLANSYS as a Delivery Manager past 4 years. He has vast experience in product development, Machine Learning on edge, complex algorithms design & development for various industries including Industrial automation, Electrical safety, Telecom etc.