LED there be light: A quick overview of switch-mode power supply design options

March 20, 2014

Lifetime, form factor, packaging, a range of colors - from the outside, it would appear as though LED lighting has everything going for it. But for de...

Lifetime, form factor, packaging, a range of colors – from the outside, it would appear as though LED lighting has everything going for it. But for design engineers, as usual, there’s a lot more to the story.

Driving multiple high-power LEDs in switch mode is by no means a trivial task, assuming factors such as uniform brightness, dimming capability, and power factor correction play any sort of role. To the seasoned power supply designer, these requirements are all in a day’s work; “driving LEDs,” after all, is just another way of saying “designing a suitable power supply.” But if you’re not an experienced power supply engineer, the design proposition can be more than a little intimidating.

Don’t let that stop you.

Thanks to significant demand in recent years for LED lighting solutions, there are plenty of options for you to get started building your power supply, whatever your level of engagement. If your goal is to design the entire luminaire, there will be other design considerations, including thermal management and optics. But for the purposes of this article, we’re focusing strictly on the electrical power supply.

Before you begin any power supply design, consideration must be given to the load. Here are a few things to consider before we get lit:

1. Power requirement – How many LEDs will you be driving? Are you driving 1 W, 3 W, or 5 W LEDs? Is the number of LEDs in each string fixed, or does your supply need to accommodate a range of output voltages? And how bright do you need your source to be? Cree offers an excellent online tool to help you determine how many LEDs you’ll need for your application.

2. Connection scheme – Are you driving your LEDs in series, parallel, or a combination of both? A series configuration is often recommended when LED brightness must be consistent across the string. But if output voltage is a concern, you may want to arrange them in parallel.

3. Forward voltages – While VF varies from LED to LED, there is also variance in typical forward voltage among different colors or dice technologies. Avago, for example, indicates the following for their ASMT-Ax00 1 W devices:

4. Features – such as dimming or power factor correction. Each will result in increased design complexity. Dimming can be achieved by varying the continuous forward current of the LED, or through pulse width modulation. A low-cost microcontroller with PWM output affords maximum flexibility and control, but it must be integrated carefully with the power circuitry. As for PFC? If traditional power factor correction isn’t in the cards due to size or budgetary constraints, you have other options. On Semiconductor, for instance, offers a single-stage, high power factor LED drive solution based on their NCL3000 critical conduction mode controller.

5. Topology – One doesn’t want to seem biased, but having grown up in a semiconductor house I tend to favor switch-mode anything. (Some of my best friends are linear designers.) A major selling point of both LED lighting and switching power supplies is efficiency; why not design the supply accordingly? With that in mind, consider the following: Is your application DC or offline? If it’s offline, will you require isolation or universal input? Do you like your bucks synchronous or asynchronous? Each topology has its merits and pitfalls relative to your application requirements.

An important final step in preparing for your design is to decide on your level of engagement. Again, seasoned power supply designers may have an easier time starting from scratch, but few of us can truly call ourselves power supply designers. Here are three ways to proceed depending on your ambition:

Buy an off-the-shelf power supply

The easiest way to light up your LEDs is to let someone else do it, although for us engineers this is usually the least exciting option. If you decide to go this route, however, you do have some great choices. Mean Well’s offline LED power supply comes nicely packaged for indoor and outdoor applications, and it’s well equipped with features such as dimming, integrated protections, PFC, and universal AC input. In marketing parlance, this is little guy is “feature-rich”; there are more basic alternatives out there if needed.

Modify a proven reference design

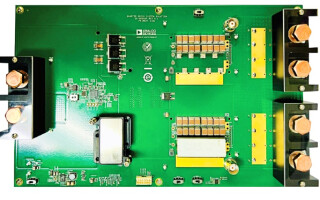

If you’re new to power supply design, this may be the best way to go, especially if you are not confined to a proprietary design. Some semiconductor giants, such as TI and STMicroelectronics, publish complete reference designs on their websites that include original schematics, bills of materials, application notes, and in some cases even Gerber files. Check out these reference designs from TI, STMicroelectronics, and Linear Technology for examples of tried-and-true starting points. And, please, keep it classy: if you’re modifying a supplier’s reference design, keep that supplier on your bill of materials throughout design, prototype, and production.

Go all-in

If you want to design your own supply from scratch, there really is nothing stopping you, except maybe a disinclination for singed fingertips and smoking hair. Importantly, going all-in doesn’t mean “going alone.” Life is too short to design in a vacuum; find a community of peers and experts, such as element14, to ask questions and share ideas.

As with reference designs, when it comes to research your best bet is to start with the suppliers. Cree, as mentioned above, offers some useful design guidance. TI offers design assistance with block diagrams and their online PowerLab Reference Design Library. Linear Technology offers designers an assortment of application and design notes and reference circuits on their website, and similar resources from STMicroelectronics, NXP, and On Semiconductor help shed light on LED power supply design.

Fortunately, there are good options for economical schematic capture and layout software for the design phase of your project. And when you’re ready to start building, affordable PCB services are available at your fingertips, with instant quoting and extremely fast turnaround.

For professional engineers and makers alike, going all-in is the most fun option – and with access to a global knowledge base, affordable circuit design software, and world-class prototyping facilities, there has never been a better time to be your own ODM. So, LED there be light.

David Finch is Technical Marketing Manager at Newark element14.