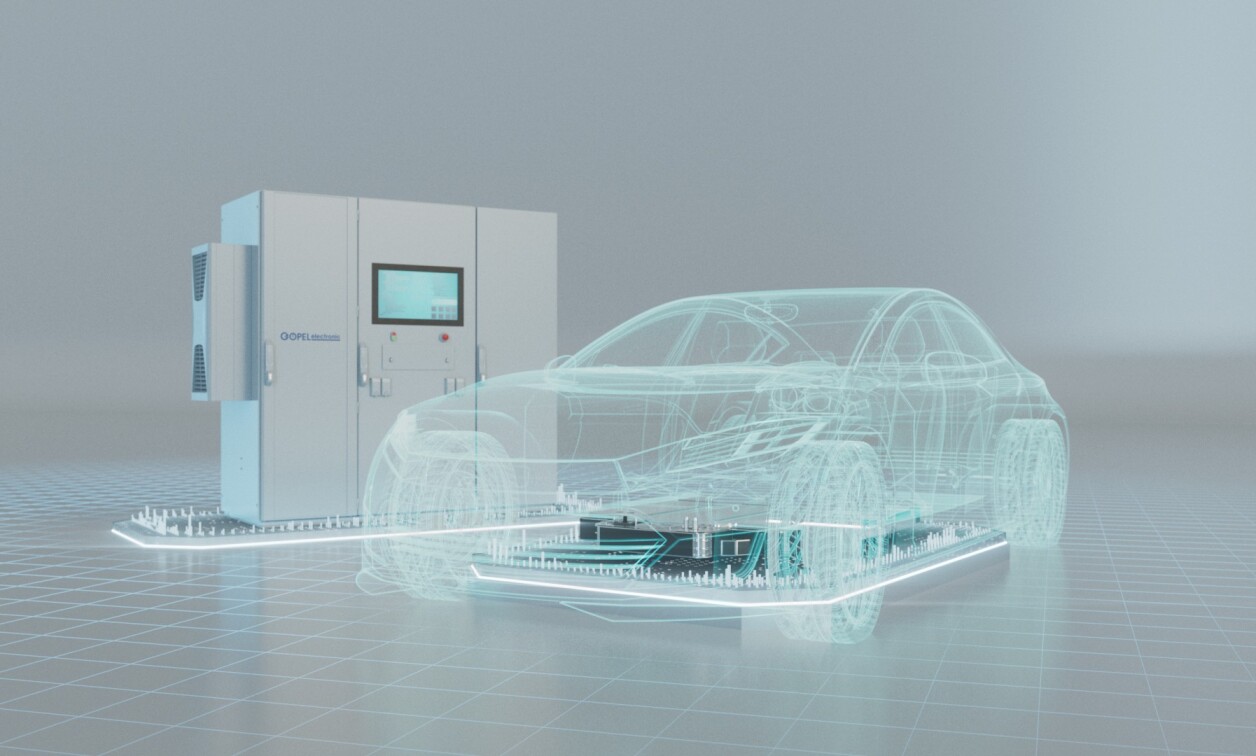

GÖPEL electronic Introduces Versatile Battery Test Solution with CAN-BUS Integration and Real-Time Data Reporting

July 14, 2025

News

GÖPEL electronic designed a powerful and fast configurable battery test bench that features a modular design and high flexibility for streamline testing of battery cells. It contains a central measurement technology unit with a computer and monitor, a control cabinet, and a unit with all power electronics.

The battery test bench offers a power range up to 500 kW and tests in the voltage range up to 1,000 V DC with test currents of up to 800 A DC. Insulation tests can be performed with up to 7.5 kV. Services offered encompass safety and operational testing, which examines cell status, battery AC impedance, AC behavior dynamics, and detect major defects. The results provide information about electrochemical processes in the cell, aging effects, and internal resistance fluctuations across different frequencies.

According to the press release, the GÖPEL electronic test system connects with the battery management system (BMS) via CAN-BUS. The battery is charged with a prescribed and defined charging pulse, discharged, and finally the “state of charge” is checked. After the battery is discharged, the energy required for this is fed back into the power grid by the test solution, ensuring high energy efficiency and cost savings.

All test results are routinely transferred to a database in the production department in independently configurable reports. Ahead of delivery, the system inspects quiescent current to avoid unnecessary battery drain, ensures the required charge level, extracts final sensor data, compares error memory logs, and uploads the end-user software to the battery.

For more information, visit goepel.com/en/automotive-test-solutions/emobility/powertrain/battery-test