Integrated SoC Shrinks the Size of the 4-20 mA Smart Transmitter

February 18, 2025

Blog

Smart transmitters can normalize gain and offset, linearize the sensor by converting its analog signal to digital, process the signals with arithmetic algorithms resident in the microcontroller, convert back to analog, and transmit the result as a standard current along the loop. They also add the capability for digital communications, which share the twisted-pair line with the 4-20 mA signal. The resulting communication channel allows for transmission control and diagnostic signals along with the sensor data. The SoC that integrates AFE, microcontroller, HART®, and 4-20 mA transmitter technology allows for the small size of the 4-20 mA smart transmitter.

Introduction

The 4-20 mA current loop offers a common technique for transmitting sensor information such as temperature and pressure in industrial process-monitoring applications. Current loops are particularly useful when the information must travel a long distance to a remote location since signals are relatively insensitive to noise, and power can be derived from a remotely supplied voltage. This article will briefly introduce a 4-20 mA system, its evolution, and a chipset to shrink the size of the overall solution and improve reliability by minimizing the number of external components.

4-20 mA Sensors Overview and Evolution

In a simple 4-20 mA system (Figure 1), the output voltage from a sensor is first converted to a proportional current, where 4 mA represents the sensor’s zero-level output, and 20 mA represents the full-scale output. A receiver at the remote end converts the 4-20 mA current back to a voltage, which can be further processed by a computer or a display module.

Figure 1. Simple 4-20 mA system.

Industry demand led to the development of a smart transmitter (Figure 2) that uses a microprocessor and data converter to condition the signal remotely. It can normalize gain and offset, linearize the sensor by converting its analog signal to digital, process the signal with arithmetic algorithms resident in the microcontroller, convert it back to analog, and transmit the result as a standard current along the loop.

Figure 2. Smart transmitter.

When an instrument is calibrated and working properly, its output signal should stay between 4 mA and 20 mA, but sometimes the process conditions deviate from the normal operation. In this case, a compliant transmitter can output up to a maximum of 20.5 mA. Its output signal is then out of range and located in the saturation region. A similar but smaller saturation area is located at the bottom of the measuring range.

Smart measurement devices can detect internal faults, like a sensor or a converter failure. When that happens, the microprocessor of a compliant instrument will set the output signal to 3.6 mA or 21.0 mA, depending on how the user has set the failsafe mode.

The signal level of the failure information (Figure 3) is standardized by the NAMUR NE43 recommendation.1

Figure 3. NAMUR NE43 recommendation.

The current available to power the transmitter electronics is therefore limited to about 3.5 mA, and this must be carefully considered when selecting devices for this application.

A further enhancement has been the addition of digital communication capability, which shares the twisted pair line with the 4-20 mA signal. This combination allows for the transmission of control and diagnostic signals along with the sensor data.

The communication standard is the HART protocol, which employs frequency shift keying (FSK), where bits 1 and 0 are represented by the frequencies of 1200 Hz and 2200 Hz. Sine waves of these frequencies are superimposed on the sensor’s DC analog signal to provide simultaneous analog and digital communications (Figure 4). The 4-20 mA analog signal is not affected since the average value of the FSK signal is always zero.

Figure 4. Simultaneous analog and digital communication.

The HART command set (Figure 5) provides uniform and consistent communication for all field devices and includes three classes: universal, common practice, and device-specific commands. All devices using the HART protocol must recognize and support universal commands such as the reading of primary variables and units. Common practice commands provide functions implemented by many devices such as calibration, self-test, and multivariable reading. Device-specific commands represent functions that are unique to each field device.

Figure 5. Example of information provided by a HART sensor.

Each HART device has a 38-bit address that consists of the manufacturer ID code, device type code, and device unique identifier.

Ultra Low Power 4-20 mA Sensor Transmitter

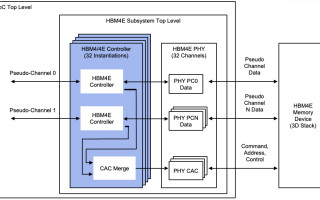

The MAX12900 is an integrated transmitter that includes 10 building blocks (Figure 6).

Starting from the left, the sensor data received from the microcontroller, arranged into coarse (PWMAP) and fine (PWMBP) PWM signals, are buffered, summed together, and converted to their voltage level representation via a low-pass filter (OP1 block). In the example in Figure 6, the coarse gain is set to 1 (R5/ R3), while the fine gain is set to 1/66 (R5/R4). OP3 in combination with a precision voltage reference and an external MOSFET (Q1) implements a precision voltage-controlled current source. In this application example, the second general-purpose amplifier (OP2) is used to measure the current loop and provide feedback to the microcontroller. Two comparators are available to monitor the supply voltage and internal LDO voltage. The power supply sequencer ensures correct startup and generates a power good signal when the LDO output reaches 90% of the final value (set by a voltage divider).

Ultra Low Power Arm Cortex-M4F with AFE and HART modem

The MAX32675C (Figure 7) is a highly integrated mixed-signal, ultra-low power microcontroller for industrial applications. It is based on an ultra-low power Arm® Cortex®-M4 with a floating-point unit, a rich set of digital peripherals, and an analog front end (AFE).

The AFE integrates a low-power HART modem, two 12-channel sigma-delta analog-to-digital converters (ADCs) with a programmable gain amplifier (PGA), and a 12-bit digital-to-analog converter (DAC).

Figure 6. An integrated transmitter.

Figure 7. A highly integrated mixed-signal microcontroller.

Integrated AFE

The MAX32675C provides two instances of a Σ-Δ ADC that share the multiplexed 12 analog inputs, which can be configured as differential or single ended. Each ADC has a PGA in front with eight available gains from 1 to 128. The PGA outputs are externally accessible for additional filtering. Multiple reference inputs are available to increase flexibility. The integrated 50 ppm voltage reference is programmable at 1.024 V, 1.5 V, 2.048 V, and 2.5 V. Sensors can be biased using a 16-level programmable current source or a fixed voltage source (VDD/2) (see Figure 8).

Figure 8. Integrated AFE.

ADC Features

The ADC can, on demand, automatically calibrate its internal offset and gain error and system offset and gain error and store the calibration value in dedicated registers. There are eight separate gain calibration registers for the PGA.

The self-calibration routine does not include external effects such as the source signal driving the input pins, which can change the offset and the gain of the system.

A system calibration enables the calibration of the system zero scale and system full scale by presenting a zero-scale signal or a full-scale signal to the selected input pins and initiating a system zero-scale or system gain calibration command.

As an alternative to the automatic generation of the system calibration values, values may be directly written to the internal calibration registers.

Calibration values are applied to the conversion results stored in the ADC_DATA register according to Equation 1:

Where:

ADC_DATA is the ADC data result destination register.

Conversion is the ADC’s conversion result before calibration results are applied.

ADC_SELF_GAIN [1:128] is the internal gain correction value for the selected gain.

ADC_SELF_OFF is the internal offset correction value. ADC_SYS_GAIN is the system gain correction value.

ADC_SYS_OFF is the system offset correction value.

The configurable digital filter has selectable notch frequency and selectable data rates.

The simultaneous 50 Hz/60 Hz rejection finite impulse response (FIR) filter provides well over 90 dB rejection of 50 Hz and 60 Hz at 16 SPS and significant rejection of their harmonics. The 50 Hz and 60 Hz FIR filter settings provide a lower level of attenuation for those frequencies but at a faster conversion time (40 SPS) than available with the simultaneous 50 Hz/60 Hz FIR filter.

The sinc4 setting enables a fourth-order SINC filter that can operate at a continuous data rate up to 1989 SPS for 24-bit accuracy and 15360 SPS for 16-bit accuracy.

The sequencer is a powerful feature that allows a sequence of commands to be programmed into the sequence buffer registers (Figure 9). The completion of a sequence can be configured to generate an interrupt.

There are eight registers to store the ADC conversion output that can be used by the sequencer.

Figure 9. Example of sequencer use.

Figure 10. AFE configured for thermocouple measurement.

There are also eight lower/upper comparison threshold registers associated with the eight conversion registers. The comparison result is stored on the status register.

AFE Configured for Thermocouple

Measurement

The AFE can be configured for measuring a temperature using a thermocouple (Figure 10). The thermocouple voltage is measured using a precision voltage reference, while a separate sensor must measure the temperature at the cold junction. This one can be measured for example with a resistance temperature detector (RTD).

For thermocouple measurement, PGA gain is set to an appropriate value according to the type used. A K-type thermocouple produces a maximum voltage of 54 mV, and using a PGA gain of 32 results in an output of about 1.7 V. The thermocouple is biased to VDD/2 (AIN5) using the internal voltage generator.

For cold-junction temperature measurement using an RTD, the current source IDAC0 is set to provide 220 μA on AIN10. The current will flow through the RTD and the reference resistor RREF, creating a voltage drop of 800 mV across RREF that is used as the reference voltage for the measurement. Since the same current flows through the RTD and RREF, the conversion data will be the ratio of the RTD resistance to REF.

HART Modem

The device integrates the modulation and demodulation of the 1200 Hz/2200 Hz FSK signals. The modem (Figure 11) has very low power consumption and needs only a few external components due to integrated signal processing. An input signal is sampled by the ADC followed by a digital filter/demodulator. The modulator provides a clean signal with phase-continuous switching between 1200 Hz and 2200 Hz. An SPI interface is used for the configuration of the peripheral register, while communication uses the UART.

Figure 11. An integrated HART modem.

Figure 12. Smart transmitter implementation.

Smart Transmitter Implementation

The combination of the MAX12900 and MAX32675C allows the design of a smart transmitter (Figure 12) using few external components, shrinking the size of the overall solution. The MAX32675C is available in an 8 mm × 8 mm package, while the MAX12900 is available in a 5 mm × 5 mm package.

Conclusion

Combining the MAX12900 and MAX32675C shrinks the size of a 4-20 mA smart transmitter, enhances flexibility by supporting multiple sensor types, and improves system reliability. Multiple reference inputs and dual ADCs increase system redundancy. The comparators and the spare operational amplifier allow the monitoring of critical parameters such as the supply voltage and the output current, simplifying SIL implementations.

Reference

1NAMUR—User Association of Automation Technology in Process Industries.

About the Author

Franco Contadini has over 35 years of experience in the electronics industry. After 10 years as a board and ASIC designer, he became a field applications engineer supporting industrial, telecom, and medical customers and focusing on power and battery management, signal chains, cryptographic systems, and microcontrollers. Franco has authored several application notes and articles on signal chains and power. He studied electronics at ITIS of Genova.