Type-C USB connector to the rescue

February 13, 2015

Tired of carrying lots of chargers on the road? Or even having so many different types stuck in a drawer? I definitely fall into both camps, which is...

Tired of carrying lots of chargers on the road? Or even having so many different types stuck in a drawer? I definitely fall into both camps, which is odd because I’m currently using three mobile products from the same company (Apple) on the road. My iPhone uses one connector, my iPad a second, and my Mac laptop a third. That makes no sense to me.

Here comes the USB Type-C connector to the rescue. The story from the OEMs is that they’re going to adopt this new connector on ALL devices, including the displays, which can better act as a charging and data hub. Let’s hope so.

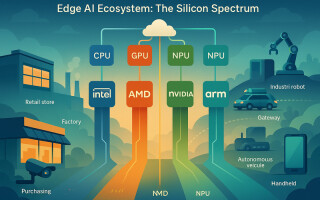

Coming in at 2.4 mm high, the Type-C connector is smaller than the more common USB Type-A connector. Yet the spec is calling for a power rating of 100 W. So that’s enough to power and/or charge most portable devices. You can see in the image how the different technologies have morphed into the latest specification for Type-C.

The 24-pin double-sided Type-C connector reversible provides four power/ground pairs, two differential pairs for the USB 2.0 data bus, and four pairs for a high-speed data bus. Some Type-C cables will be “active,” meaning that they’ll contain a controller chip that will allow the host to identify itself and its required power level.

Unfortunately, the Type-C spec is still somewhat in flux. The best way to combat such a situation is to employ a programmable solution, such as the PSoC-based CCG1, developed by Cypress Semiconductor. According to the company, designers can integrate the CCGI in a matter of weeks, as opposed to the months that it might take to build a more traditional design.

Based on an ARM Cortex M0 core, the CCG1 controllers integrate the voltage- and current-monitoring circuitry that’s needed for power adapter applications. In addition, this configuration allows the firmware to be updated during product development, in the production line, or in the field. This is a feature that comes in handy as the spec is being sorted out.