Smart factory: CONTACT Software and Mitsubishi Electric become IoT partners

September 04, 2019

Blog

CONTACT Software is a new member of Mitsubishi Electric's e-F@ctory Alliance.

CONTACT Software is a new member of Mitsubishi Electric's e-F@ctory Alliance. This partner network supports Mitsubishi Electric's Factory Automation division in providing its customers with tailor-made complete solutions for smart connected manufacturing.

Mitsubishi Electric is one of the world's leading suppliers in the field of factory automation. Headquartered in Tokyo, the company not only supplies its customers with control and drive technology, robots and much more, but also accompanies their industry 4.0 projects at all levels. In the future, the Factory Automation EMEA division will also rely on CONTACT Elements for IoT to intelligently network production facilities and bundle them into a single platform.

"With Elements for IoT, our customers can implement complete solutions for the digital factory that are individually tailored to their requirements and take given infrastructures into account," says Thomas Lantermann, Senior Business Development Manager e-F@ctory Solution at Mitsubishi Electric Europe, Factory Automation EMEA. "CONTACT Software adds a strong player to the e-F@ctory Alliance".

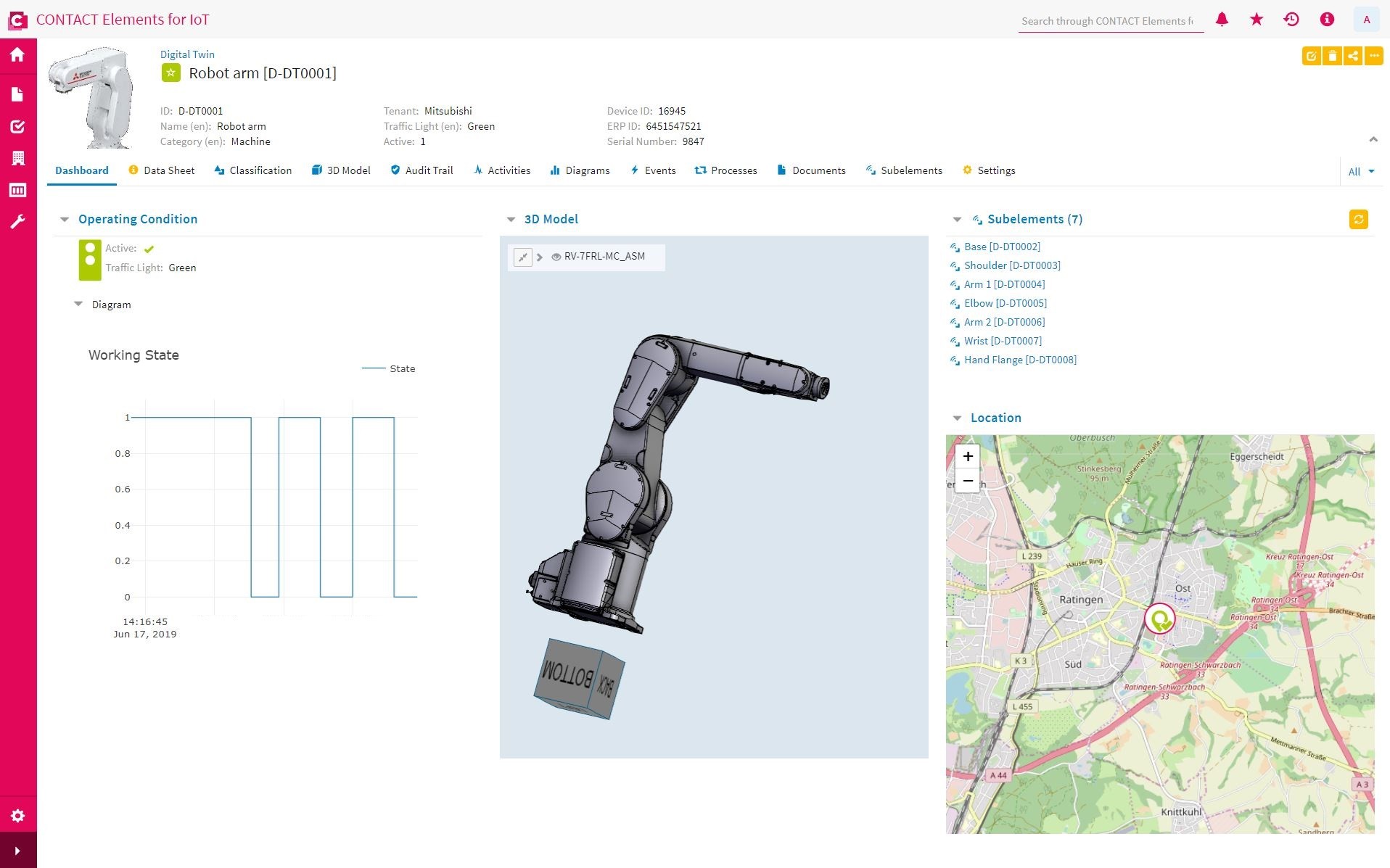

CONTACT Elements for IoT generates digital twins of Mitsubishi's industrial robots to visualize and further process the operating data of the integrated condition monitoring. Sub-process systems of a comprehensive process context can be supplemented, for example by automatically triggering predefined actions - for example, when production processes are to be optimized or maintenance tasks are pending.

Elements for IoT increases productivity and quality in production

The openness, connectivity and breadth of solutions offered by CONTACT's technology platform provide Mitsubishi Electric's customers with comprehensive options. Companies can benefit from end-to-end shop floor management that is directly linked to the internal enterprise IT and continuously increases process performance.