How Semiconductor SoC Concepts are Transforming Sensors

January 18, 2021

Story

The integration of many components onto a single die revolutionized the consumer electronics industry. Instead of each feature having its own integrated circuit (IC), a system-on-a-chip IC integrates these distinct functions on a single die or substrate in order to reduce power, shrink the size and lower the cost of a product.

The integration of many components onto a single die revolutionized the consumer electronics industry. Instead of each feature having its own integrated circuit (IC), a system-on-a-chip IC integrates these distinct functions on a single die or substrate in order to reduce power, shrink the size and lower the cost of a product.

The first SoCs date back to the 1970s when many components were integrated into single chips to control the nascent digital watch market. This allowed the watches to be smaller in size and provide sufficient battery life. After watches, calculators started integrating new SoCs that made the devices lighter and substantially cheaper. By the 1990s, IC companies started embedding microcontrollers with DSPs and other components into system-level chips that drove the rapid adoption of handheld devices (games, instruments, phones), peripherals and other products. By taking the IC with the most intelligence, integrating it with other components and sharing its smarts across these additional functions, the electronics industry entered a new era of inventiveness.

Today, SoCs are in most electronic products from smartphones, TVs, and automobiles; to IoT devices, and embedded systems. The ability to integrate many functions onto a single chip has led to an explosion of highly powered devices throughout all segments of the electronics industry, benefitting our daily lives. The SoC concept is now expanding to other products, such as sensors, that will drive the next wave of innovation.

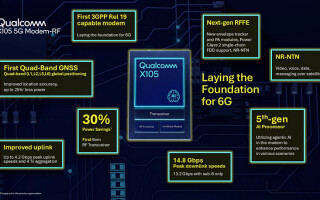

(Figure 1: SoC – Smartphone AP Example)

System-in-a-Sensor: Bringing SoC Concepts to Sensors

As most sensors detect or measure physical properties, they have not been integrated into ICs. Acting as a bridge between the analog and digital worlds, and often being location dependent, has made adding their full capability into an integrated circuit that sits on a centralized PCB extremely difficult. However, as a standalone sensor module, we can utilize the SoC concept in creating a new generation of sensors that are more efficient, reliable, flexible and functional.

Like SoCs, smart sensors are not new as these integrations started in the 1970s in advanced IR surveillance and warning systems. Originally commissioned by the military, the advances in computing power, component miniaturization and software algorithms are now opening up new doors for advanced sensor modules across industries and applications. Integrating a microcontroller or DSP in the sensor module gives it the intelligence to offer additional capabilities such as self-calibration, self-identification, digitization of sensor data, and wireless communications.

Today, smart sensors are everywhere, including homes, automobiles, and factories. We have all experienced situations where a motion sensor drives lighting and/or the HVAC in a building, a distance sensor turns a camera or spotlight on and off, a water/humidity sensor instructs a sprinkler system to turn on, and an alarm sensor that sends a wireless notification in case of a breach. This is accomplished by having the base sensor(s) directly interact with a microcontroller or DSP and a communications module. An integrated smart sensor solution is designed to work better than trying to piece-meal all the components together. The tighter integration reduces latency, better utilizes system resources and increases overall performance.

(Figure 2: Smart Sensor Example)

Taking it a step further, the new System-in-a-Sensor concept brings advanced capabilities that are application or use-case specific and can be adjusted even after a sensor is deployed in the field. Much like a smartphone’s usage pattern is controlled by a user, a system-in-a-sensor’s usage pattern can be controlled either by an operator or based on system events.

Parallels with the Evolution of Smartphones

Most of the computing functions in a smartphone are driven by an application processor (AP) that is an extremely intricate SoC controlling many of the functions of the phone including the display, applications, power and communications modules. The AP is very intelligent. Depending on what you are trying to do with the smartphone, the SoC structures itself to optimize the performance for the desired function. It is like a swiss army knife. Depending on what you are trying to do, it pulls out the right tool so you can do it as efficiently as possible.

Shouldn’t sensors have this same level of ingenuity? As many sensors are powered by ASICs, microprocessors, controllers or DSPs, they can be architected to be flexible and intelligent to optimally perform different functions like an AP does on a smartphone. Having one sensor that can be integrated into many devices and then configure itself based on the immediate need is where the technology is heading. This can be seen in the NimbleSenseTM architecture deployed in the Superior Sensor Technology pressure sensor products. One sensor can support a wide array of pressure ranges without any degradation in accuracy, and various features can be turned on and off depending on the application for its use.

System-in-a-Sensor: Benefits

Bringing intelligence into a system-in-a-sensor implementation can provide lots of benefits. For example, by procuring the same system-in-a-sensor for numerous projects, you gain the benefit of lower inventory costs, simplified manufacturing and a more straightforward supply chain. As a manufacturer, you only need to worry about building and creating inventory of one system. This lowers your inventory costs and simplifies your manufacturing as you do not need to reconfigure production lines for each product. Further, by using one sensor for multiple purposes and projects, you significantly reduce your supply chain complexity by procuring and inventorying a single part. You gain the benefit of economies of scale as your business ramps up.

In addition, a sensor can be configured ‘on the fly’ to support various applications and features. This enables engineers to more rapidly design their products by integrating the same sensor in many devices and applications. Development cycles will be shorter, and engineers can freely optimize their design throughout the development phase without the risk of having to change to a new component that can possibly cause production delays.

Finally, overall system performance is enhanced due to the customizable capabilities of the system-in-a-sensor. If architected correctly, like a smartphone AP the sensor will ensure peak performance across many use cases. This is due to the sensor being optimized for flexible general use (e.g., supporting multiple pressure ranges while maintaining the same levels of accuracy) and having the ability to turn on specific features for certain applications. Like an SoC, the system-in-a-sensor is designed to operate at maximum capability across a wide array of applications and configurations. Moreover, a company can quickly bring out derivatives to expand product lines and further segment its offerings since one sensor solution can be deployed to support many different products.

About the Author

Anthony Gioeli is the Vice President of Marketing at Superior Sensor Technology, a Silicon Valley company redefining the differential pressure sensor market. He has over 30 years of experience in international sales, marketing and product management for new technologies in biometrics, wireless communications and video processing. A renown author on international business, Anthony received a B.S.E.E. from the New York Institute of Technology and an MBA in finance and new venture management from the University of Southern California