Feeding the Future: Edge AI in the Field

June 24, 2025

Blog

The agricultural sector is undergoing a major technological overhaul that some are calling the era of Farming 4.0. This agricultural revolution is marked by autonomous machines that carry a raft of sensing and processing devices. These machines collect and analyse data to make decisions in real time that improve productivity, efficiency, sustainability, and cost effectiveness.

Agriculture is increasingly being shaped by AI-powered edge computing systems. Traditional farming equipment such as tractors, combine harvesters, and irrigation systems now carry sensors and processors capable of collecting data, processing it at the edge, and turning those decisions into appropriate and timely interventions. AI-enabled systems check whether crops need more water, if the soil has the right nutrients, or if plants or livestock are being attacked by pests or diseases. Not only do these systems keep farmers informed – they are also capable of finding the right solutions with minimum human input.

AI can also lower the cost and burden of maintaining machines. Predictive maintenance uses machine learning techniques such as anomaly detection to anticipate equipment failures before they occur, based on vibration and audio data collected on the machine. This reduces maintenance costs and minimizes downtime.

Closer to the source

In industrial systems, we see data collected from a multitude of sensors being sent to the cloud for processing and analysis, to improve insights and develop longer-term strategies. The principle is the same in agricultural systems, but here, the remoteness of fields and farms makes uploading large volumes of data to the cloud unreliable. Local processing, enabled by Edge AI, solves this issue. On-chip AI capabilities allow for low-latency smart decisions, reducing the need for large volumes of data to be sent to the cloud for analysis. Devices in the form of CPUs, GPUs, dedicated ASICs, and NPUs, many with AI capabilities built in, handle this data locally. Market analysis house Grand View Research forecasts the global market size for edge AI chips to reach USD 120 billion by 2030, up from 16 billion in 2023, growing at a compound rate of 33.9% over that period.

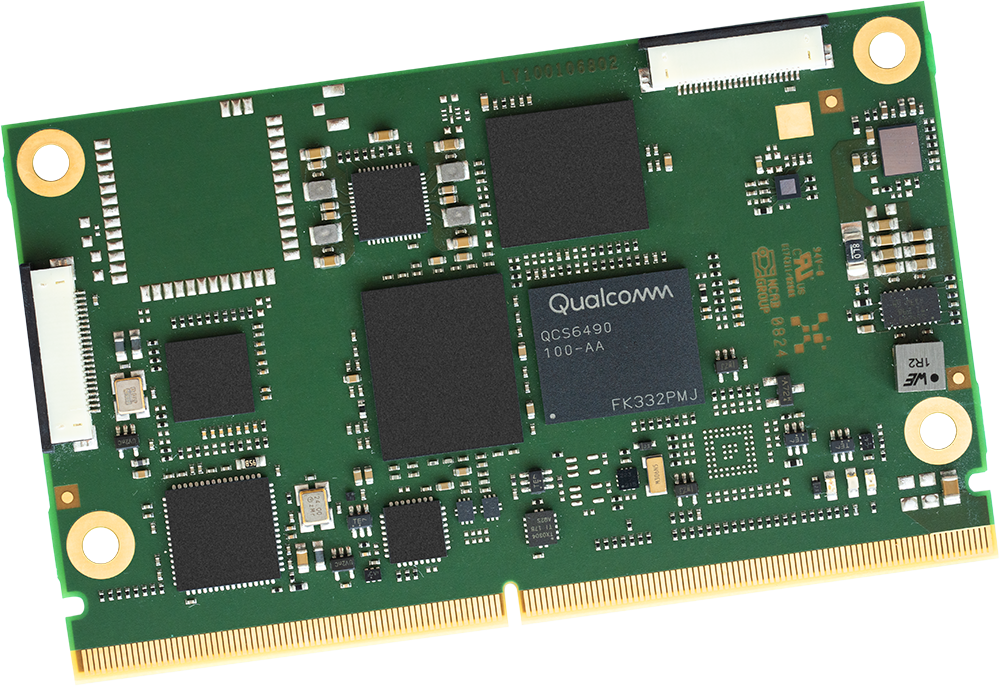

Edge AI applications are powered by embedded compute modules that harbour these AI-enabled processors. Tria Technologies provides a wide range of computer-on-modules (COMs), designed in partnership with various CPU vendors such as AMD, Intel, NXP, Renesas, and more. One notable cooperation is with Qualcomm, allowing Tria to create a new generation of compute modules around Qualcomm’s high-performance processors, Dragonwing and Snapdragon, based on the ARM architecture. The latest Tria SMARC modules are applicable to a wide range of applications that meet the needs of smart agricultural systems, providing machine vision, anomaly detection, sensor gathering and analysis, audio classification, and more.

Embedded compute modules for agriculture

AI-enabled embedded compute boards are highly advantageous for smart agriculture applications, with different options for compact size, ruggedness, flexibility and powerful computing. These small boards can be embedded in tractors and machinery, running ML and AI models locally. Tria’s portfolio of boards supports multiple cameras, easily adapted for use in agricultural autonomous robots and drones. They also support computationally intense AI applications such as Large Language Models (LLMs) for applications that require natural language processing. This will soon enable machines to respond to verbal communication.

The hardware on the embedded compute boards is built to handle parallel processing to speed up models such as CNNs (convolutional neural networks). The specialized processors can handle these tasks at great speed and at very low power, allowing them to run off batteries or solar power. Tria’s low-power, AI-enabled boards have been used in anomaly detection applications that use a combination of audio and accelerometer data to predict irrigation leaks.

The farming community is currently testing several projects relying on machine vision and ML to detect diseases in plants and livestock. One such program determines the illness plants are suffering from based on photographs of their leaves. A CNN is trained on an existing dataset of leaf images to identify the disease, resulting in an accuracy of over 96%. The plant disease can be quickly determined, with appropriate measures then taken before the disease spreads.

Machine vision is found in agricultural ‘spraying’ projects, too, which use robots and drones to water plants and selectively spray herbicide. These robots function either autonomously, by navigating through the fields using sensors, or are manually controlled via apps. One benefit of autonomous farm machinery is that driverless machines can be smaller and lighter weight, reducing soil compaction for healthier soils that require less tilling. Using machine vision, these systems can accurately pinpoint weeds to spray with herbicide so that considerably less herbicide is used. Less compacted soils and lower herbicide usage saves farmers money, provides more nutritious food, and maintains a healthy environment.

Edge AI enabled by Tria

Tria prides itself on the benefits it offers its partners and customers. The company designs its board for applications specified by its partnering companies, based around the capabilities and specifications of their devices. In addition, Tria’s partnership with Avnet (its parent company) ensures stock is available for its customers on a 15-year life cycle, so items don’t become obsolete within that time.

Tria develops and integrates boards and devices into customised systems on behalf of its customers, thus eliminating technical difficulties and lengthy development stages that design engineers undertake when introducing new products – especially now that AI is a key part of these products.

Choosing a processor for an AI-enabled applications can be a difficult task. Tria offers a wide array of system-on-modules (SOMs) built around AI-capable processors. They also offer compatible baseboards that are based on popular standards such as SMARC, as well as reference designs that provide example code for machine learning applications. These enable customers to hit the ground running with AI-on-the-edge projects. This enhances customers’ ability to react to new requirements quickly without the need for involved, time-consuming and expensive development stages, even more determining the success of their creations.

For more information, visit tria-technologies.com.