Protection and Telemetry in AI with 800 V Hot Swap

October 09, 2025

Blog

This article addresses the growing power demands of AI server environments, driven by the increasing power consumption of GPUs. It highlights the shift from 48 V to 800 V power delivery architectures. This article explores Analog Devices’ continued innovation in high voltage hot swap protection as data center infrastructure evolves.

The Future of Hot Swap Controllers in Data Centers

As AI workloads intensify, GPUs in server environments are driving unprecedented power demands—prompting a shift toward an 800 V power delivery architecture at the rack level. This elevated voltage introduces new challenges for system protection and monitoring, particularly during live tray insertion and removal. To address these challenges, a next-generation hot swap controller is required—capable of managing high voltage inrush currents while providing robust telemetry for system diagnostics and safety. Analog Devices, a recognized leader in hot swap technology at 12 V and 48 V, is now extending its expertise to support the industry’s transition to 800 V.

Why Does 800 V Matter?

Two key trends are driving the transition to higher voltage power delivery at the rack level in AI server infrastructure.

- Rising GPU Power Consumption: As GPUs continue to scale in compute performance, their power requirements are increasing significantly.

- Higher Compute Density per Rack: To maximize performance and minimize interconnect latency for large-scale AI training and inference, more GPUs are being consolidated within a single rack. This co-location improves bandwidth efficiency and reduces communication overhead by shortening data paths between accelerators.

To meet the resulting surge in rack-level power demand, the industry is moving toward a disaggregated power architecture. In this model, traditional power components such as power distribution units (PDUs), battery backup units (BBUs), and capacitor units (CUs) are relocated from the main IT rack to an adjacent power sidecar. This separation not only supports higher voltage delivery, such as 800 V, but also frees up valuable space within the rack for additional compute resources.

The Existing Approach to Power Delivery

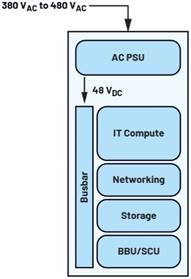

AI racks operate with a 48 V busbar (Figure 1). AC is converted to 48 VDC using in-rack power supply units (PSUs). The 48 V bus feeds IT equipment (server PSUs, GPU nodes, switches), BBUs with their own bidirectional DC-to-DC converters, and supercapacitor units (SCUs) for fast ride-through and transient handling.

Figure 1. 48 V data center power delivery to rack.

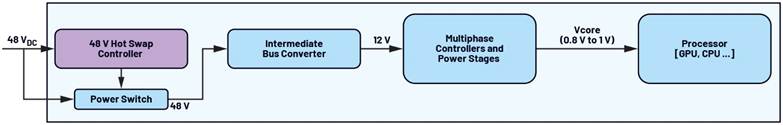

Figure 2. 48 V AI server.

Each node on a rack (for example, a server tray) requires the capability to be switched in and out during live operation. Imagine a service technician arriving on site to replace a server. It’s not practical to shut the entire rack down just to replace a single server. Doing so would be hugely intrusive to the operation of the data center, not to mention enormously expensive due to server downtime. The only time a rack would be taken offline is for a major electrical issue, related to the busbar or facility feed, etc. Instead, nodes are hot swapped, allowing the technician to remove the node, swap it, and push it back in without shutting anything else off.

During this event, the node’s hot swap controller disconnects power internally, allowing the node to be removed safely. The rack’s busbar stays energized and continues feeding all other nodes, BBUs, and SCUs. Once a replacement node is inserted, precharge circuits limit inrush before full connection, a key function of the hot swap controller. The node then boots and rejoins the AI cluster automatically (often with orchestration tools handling rebalancing).

Figure 2 shows the power distribution of an AI server from 48 V busbar to processor. The hot swap controller is clearly shown as the first interface to allow the technician to safely and efficiently remove the node.

ADI has a deep portfolio of 48 V hot swap controllers with PMBus® power monitoring such as the LTC4286 and LTC4287, which are pin-to-pin 7 mm × 7 mm QFN hot swap controllers with single and dual gate architecture. Most recently, the LTC4284 dual gate solution in a 5 mm × 8 mm QFN package was added to this portfolio.

Evolution to Higher Voltages

With the increased power load from AI processors, a new horizon in higher DC voltage distribution to the rack is emerging. ADI is on the cutting edge of these solutions and working closely with industry leaders to solve such problems.

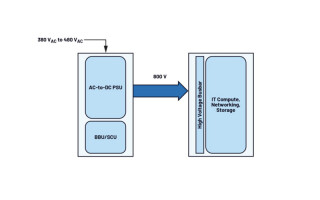

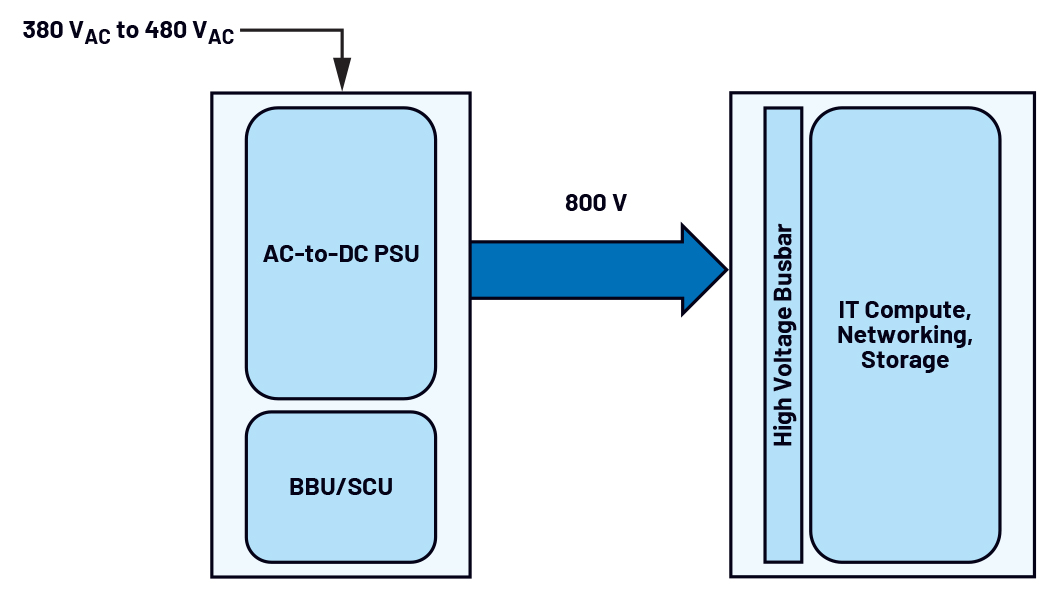

A new voltage distribution domain is defined to the rack—800 V. This is fed from a sidecar directly to the IT rack. Figure 3 shows the proposed architecture.

Figure 3. 800 V data center power delivery to rack.

The primary driver for transitioning to higher rack-level voltages is the escalating power demand per rack. As power increases, so does the current flowing through the busbars. This rise in current necessitates larger and heavier busbars to maintain acceptable thermal and electrical performance—posing significant challenges in terms of mechanical practicality and system design. By increasing the delivery voltage, the required current can be proportionally reduced, enabling the use of more compact and manageable busbar dimensions and interconnects. This shift to higher voltage is essential for maintaining scalable, efficient, and mechanically feasible power distribution in next-generation AI server racks.

It’s worth noting there can exist intermediary steps in this architecture evolution where a 48 V busbar is used in the rack. In this case, PSUs are scaled to higher powers, accepting 800 V at the rack and downconverting to 48 V to marry with existing busbars. However, this is not a longer-term state as power will be limited (maybe up to 250 kW per rack) and the goal is to allow for maximum compute capability in a single rack, driving power to 1 MW per rack by the end of the decade. PSUs and BBUs are therefore best positioned outside of the IT compute rack, as shown in Figure 3.

In the future, solid-state transformers are likely to be used to distribute high voltage directly to each IT compute rack without the need for these sidecars.

Taking Hot Swap to the Next Level

ADI has extensive expertise across the data center power domain and is collaborating with cloud service providers and semiconductor manufacturers to develop next-generation high voltage rack-level power delivery solutions.

For high voltage hot swap there are many design considerations that need to be understood and technical challenges that will need to be overcome to create the optimum solution.

- Power Density: This is a critical factor, as the 800 V hot swap circuitry ultimately resides on the server card within the IT rack. Space on these cards is highly valuable and will face growing constraints as rack densities increase, fitting more servers into each rack. As a result, high voltage hot swap solutions must be designed to occupy the smallest possible footprint.

- High Voltage Control and Protection: Transitioning to 800 V introduces significant safety challenges. While 48 V poses minimal shock risk, these higher voltages can be life-threatening. Consequently, hot swap circuitry must handle large current surges within microseconds, making precise control essential. Managing the inrush current ramp is critical to avoid damage to the rack or harm to technicians. The system must also coordinate timing, detect overcurrent or undervoltage events, and shut down gracefully when required.

- Telemetry: As the first component in the node’s power path, hot swap controllers are ideally positioned for data acquisition. They must precisely measure voltage, current, and power to meet system specifications, while also logging events such as overcurrent, undervoltage, and thermal shutdowns. In addition, they should report temperatures from the power switch (MOSFET) or nearby PCB areas. Accurate hot swap telemetry delivers significant system value by enabling real-time load current profiling, which improves energy demand forecasting. Historical current data collected at the hot swap supports predictive maintenance, such as identifying a failing PSU before it trips, and feeds into rack-level capacity planning models for power distribution. Analog Devices is actively developing new high voltage hot swap controller solutions to support emerging rack-level power architectures. By leveraging its proven intellectual property in power protection and telemetry, ADI is extending its capabilities into the 800 V domains. In collaboration with leading data center OEMs and power switch vendors, ADI’s next-generation solutions are engineered to meet the evolving requirements of hot swap systems—including compact form factors, precise high power control, and enhanced data acquisition accuracy. These innovations are critical for enabling safe and efficient operation in high voltage AI server environments.

Conclusion

This article highlights the critical shift toward 800 V power delivery in AI server racks to accommodate the increasing power requirements of advanced GPUs and support higher compute density. The new architecture involves moving power components to a separate sidecar, thereby optimizing space for compute resources in the main rack. ADI is at the forefront of this development, creating next-generation high voltage hot swap controllers that effectively manage inrush currents, offer comprehensive telemetry for system diagnostics and safety, and ensure reliable operation. By taking a system view to the evolution of rack power, developers can enable cloud server providers and system integrators to generate new insights and revenue savings.