How to Choose the Best Overcurrent Protection Device for Your Next Design

August 05, 2025

Blog

The choices vary, from traditional fuses to PPTCs and eFuses, but what is the right choice?

Introduction

Overcurrent protection is crucial in electronic systems to safeguard components from damage caused by excessive current. Several technologies exist for this purpose, including Polymer Positive Temperature Coefficient (PPTC) devices, electronic fuses (eFuses), and traditional fuses. These protection technologies have unique characteristics that make them suitable for different applications. This article compares PPTC, eFuse, and traditional fuses in terms of functionality, performance, and application suitability, helping engineers select the right protection device for their designs.

Figure 1. Traditional fuse, PPTC, and eFuse

Basic Functionality and Reset Mechanism

Overcurrent protection devices differ in their response to faults and how they reset. Traditional fuses are single-use devices that the end user must physically replace once they have blown, making them suitable for applications where failures are infrequent or fail-open scenarios are required. PolySwitch® PPTC (Polymer Positive Temperature Coefficient) devices provide resettable protection by increasing their resistance when heated, allowing them to return to normal operation after cooling down. However, their response time is slower than fuses and may not be suitable for applications requiring precise control. The eFuse protection ICs offer the most advanced protection, integrating multiple features such as overcurrent, overvoltage, and thermal shutdown. They allow for electronic resets, remote control, and programmability, making them suitable for applications that require robust and intelligent protection.

However, eFuses may not be the best choice for all scenarios. Compared to simpler devices like traditional fuses or PPTCs, their increased complexity and power consumption can be drawbacks, especially in cost-sensitive or ultra-low-power designs. Additionally, eFuses may require firmware or MCU support to unlock their complete feature set, which might not be feasible in basic or standalone systems.

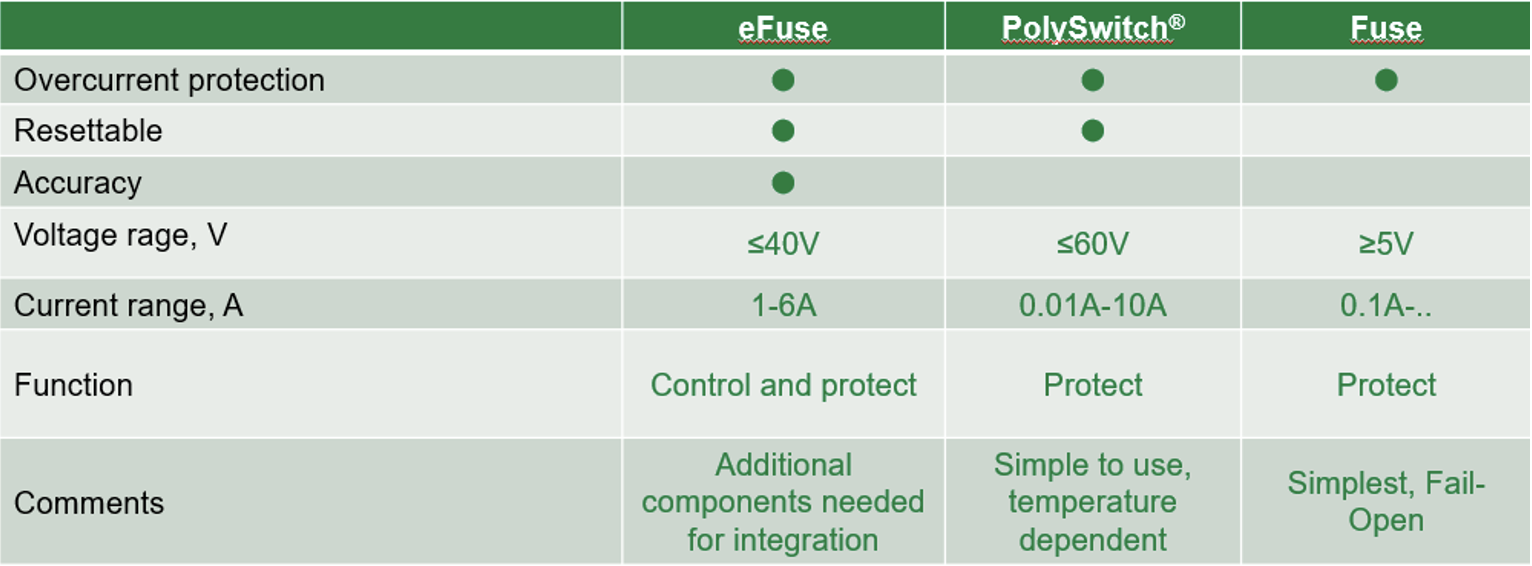

Table 1 further clarifies the differences in capabilities, reset mechanisms, and electrical ratings between eFuses, PPTCs, and traditional fuses.

Table 1. Summary comparison of key features across eFuse, PPTC, and traditional fuse technologies, including reset capability, speed, multifunctional features, and electrical ranges.

Discrete Component Approach vs. Integrated Solutions

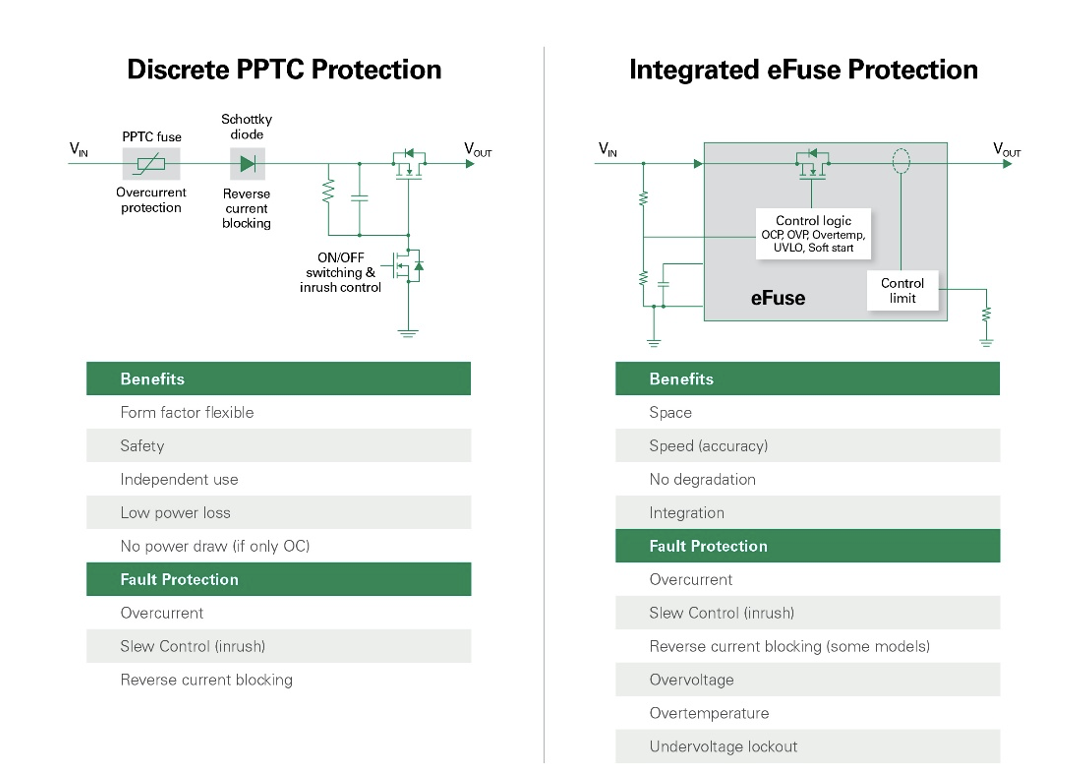

A discrete component approach involves using separate protection elements, such as PPTCs or traditional fuses, often combined with a load switch or MOSFET, to enhance control and protection. This approach offers design flexibility but necessitates the addition of circuitry to achieve comprehensive protection. It is commonly used in cost-sensitive applications or when a system designer prefers modularity.

Figure 2 (left side) illustrates a typical discrete protection circuit, which utilizes a PPTC device for overcurrent protection, a Schottky diode for blocking reverse current, and external circuitry for ON/OFF switching and inrush control.

Integrated solutions, such as eFuses, embed multiple protection features into a single package. These devices offer high reliability, fast response times, and programmability, significantly simplifying circuit design. Integrated solutions also offer additional benefits, including soft-start functionality and fault logging.

Figure 2 (right side) illustrates a typical eFuse-based integrated solution that combines overvoltage protection, current limiting, and logic control in a compact and easy-to-implement form.

Figure 2. Comparison of Discrete PPTC Overcurrent Protection and Integrated eFuse Protection

Technology Comparison by Application

The following sections review three typical applications where overcurrent protection is essential, with technology recommendations for each use case.

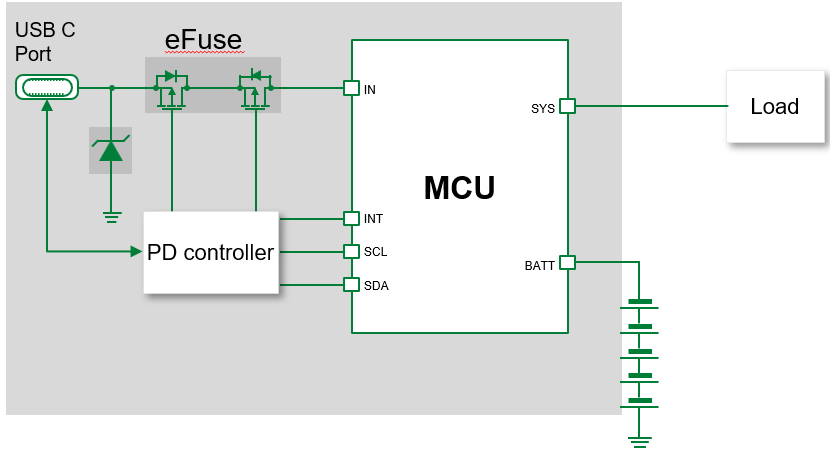

Charging Device Protection: USB-C Example

Figure 3 illustrates a typical USB-C charging device protection circuit. An eFuse with reverse current protection safeguards the power path between the USB-C port and the system, while a PD (Power Delivery) controller facilitates the negotiation of voltage and current. The MCU manages system operations, and additional protection elements (like TVS diodes) would typically be placed near the USB-C lines.

Figure 3. Example of USB-C charging protection using an eFuse and PD controller. The eFuse handles overcurrent and reverse current protection, while the PD controller negotiates power delivery with the host.

Small Motor Control (Below 24V, >1A)

For motor-driven applications, protection against stall currents and short circuits is crucial.

- PPTC devices are the primary recommendation, providing simple, cost-effective, and resettable protection for battery-powered motors, especially in consumer or portable applications.

- Switches and TVS diodes are also recommended for additional power control and transient voltage protection.

- eFuses are a good recommendation if the application has limited onboard space, requires more advanced control, or if the MCU supports intelligent fault management. However, eFuses may not be ideal for cost-sensitive designs or very low-power motor control, where the complexity and added features of eFuses are unnecessary and may increase system cost or power consumption.

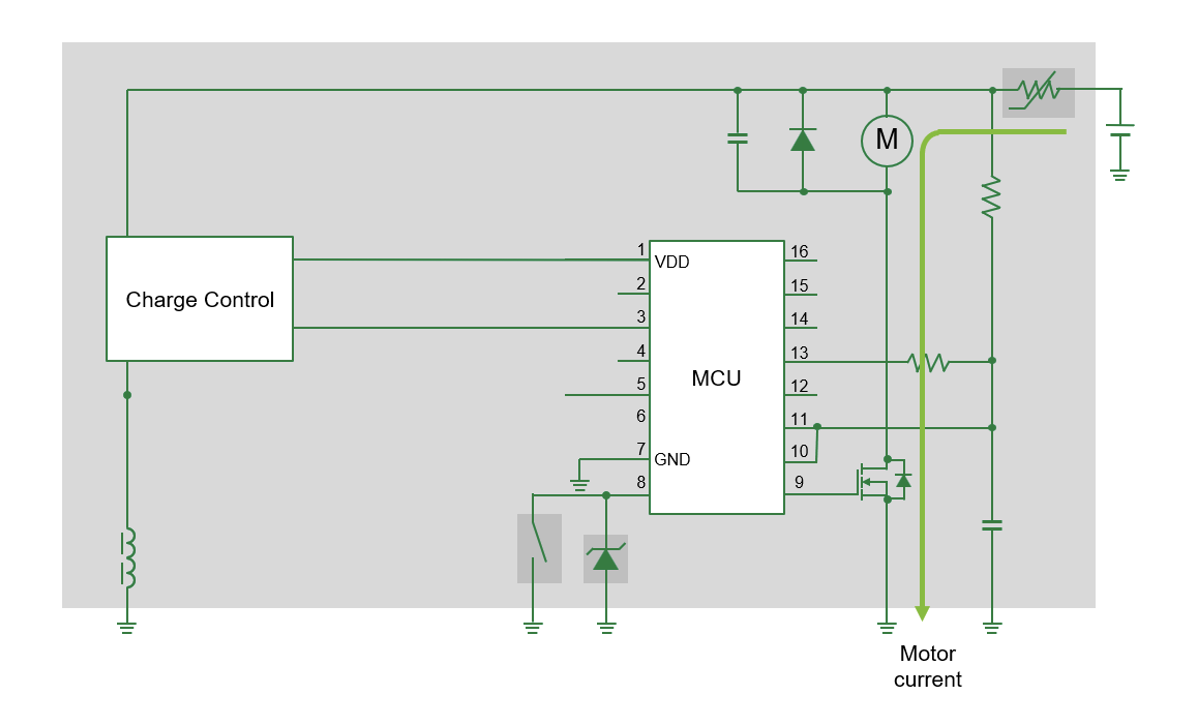

Figure 4 below shows an example of a motor control circuit using a PPTC for resettable overcurrent protection. The system includes an MCU that drives the motor and monitors current, while other discrete components manage additional protection and power control.

Figure 4. Example of a portable motor control circuit powered by a 3.6V Li-ion battery. A PPTC device provides resettable overcurrent protection, while the MCU controls switching and monitors motor current.

Communication Protection (RS-485 Ports, 5-60V, <1A)

Communication interfaces are susceptible to surges, transients, and overcurrent events.

- PolySwitch® PPTC devices are the best recommendation for providing resettable short-circuit protection and mitigating transient damage.

- TVS diodes and gas discharge tubes (GDTs) can be paired with PPTC devices for comprehensive surge protection.

Figure 5 below shows a protection example for an RS-485 communication interface, where TVS diodes are used to suppress transient voltages and protect the transceiver. PPTC devices were added to the design for resettable overcurrent protection.

.png)

Figure 5. Example of RS-485 transceiver protection using TVS diodes for surge suppression. PPTC devices can be added in series with A and B lines to enhance overcurrent protection.

Conclusion

Choosing the proper overcurrent protection technology depends on the application’s requirements for reset capability, response time, and power management. Traditional fuses remain relevant for high-current, one-time protection applications, while PPTC devices provide a simple, resettable solution. eFuses, with their programmable features, are ideal for modern power management systems that require precision and flexibility.

Electronics design engineers must carefully evaluate these factors to optimize their circuit protection strategies.

References

- Circuit Protection Product Selection Guide

- Fuseology Design Guide

- Fuse & Accessory Selection Guide

- Protection ICs eFuse Overview Technology Brief

Paulius Juskevicius is a Strategic Marketing Manager for the Electronics Business Unit at Littelfuse. Paulius joined Littelfuse in 2016 as a field application engineer for the EMEA region. His current responsibilities include the management of marketing activities for new product launches and performing marketing studies and feasibility analysis for new product ideas. Paulius earned his master’s in electrical engineering from Kaunas University of Technology.