We Must Embrace Innovation Where it Matters Most—on the Fab Floor

December 03, 2025

Story

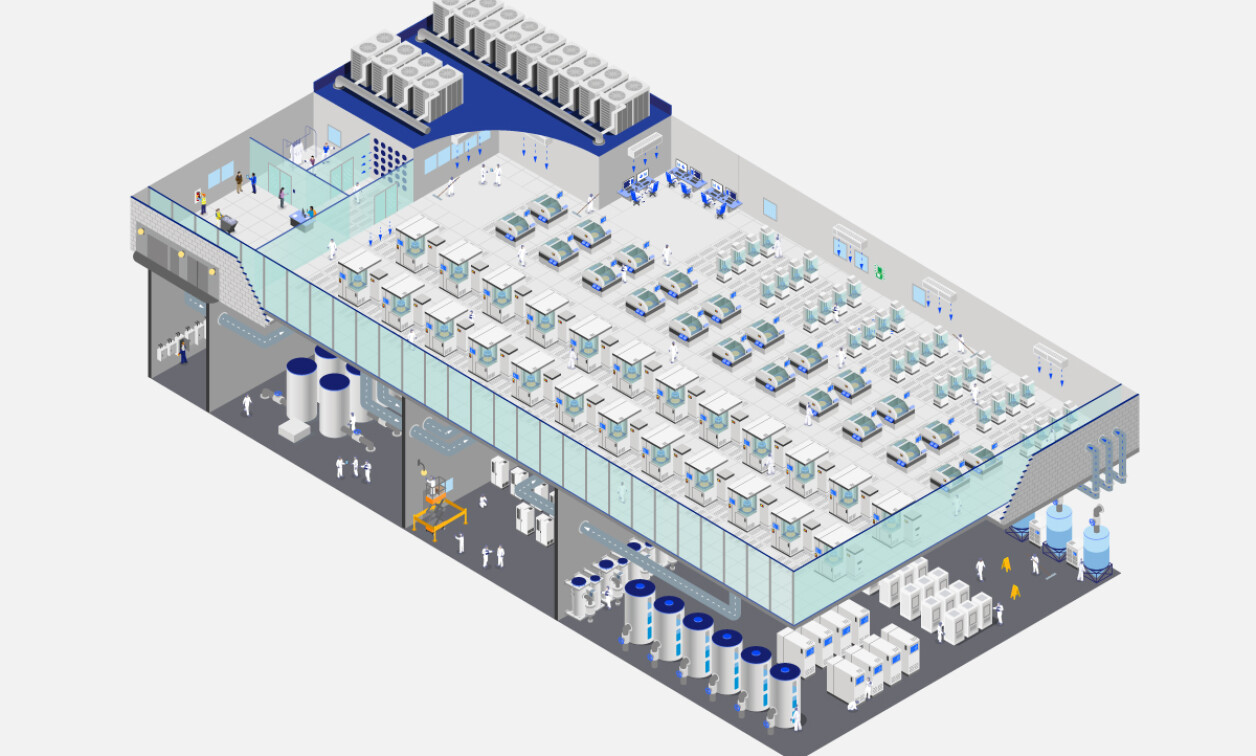

The domestic semiconductor industry is at a critical juncture — with substantial investments, supportive policies, and soaring demand for artificial intelligence. Yet as the U.S. ramps up domestic production, I can’t help but wonder: are we on the cusp of unprecedented growth? Or are we teetering on the edge of a cliff?

As processes continue to advance (toward 3nm, 2nm nodes), the margin for error continues to shrink. Yet, high yields and peak efficiency are non-negotiable. Any downtime is tremendously costly — both financially and competitively. It’s time to take the management of these complex facilities seriously. We must leverage the most advanced technologies to optimize operations, boost efficiency, and ensure stringent conditions are consistently met.

IoT, data intelligence and predictive analytics may hold the key to achieving the precision, reliability, and real-time adaptability needed for our industry to soar.

Digitizing the Facility

Semiconductor fabs generate massive amounts of data from equipment, environmental controls, and production processes.

By digitizing facility services, we can leverage this data for actionable insights. A data intelligence platform like ABM Connect™ streamlines and displays analytics tailored to answer front-line questions instantly. This solution features an integrated IoT hub for visibility and task validation such as:

- Work completion against planned routes

- Quality performance and inspections

- Recognition patterns and performance trends

- Training compliance

- Safe workplace observations

This provides real-time metrics, robust reporting, and up-to-date KPIs. It also helps tackle compliance and audit challenges while driving continuous improvement.

Predictive Maintenance

Traditional reactive or preventive maintenance is expensive and inefficient. Highly specialized, expensive tools like photolithography machines, etchers, and deposition systems are prone to operating challenges. A failing laser in an EUV system or a vacuum pump failure can stop a line — and have a material impact on production yield.

Predictive maintenance (PdM) shifts from reactive or scheduled maintenance to a data-driven, just-in-time approach. By leveraging PdM, we can minimize disruptions and extend equipment life. It’s the difference between changing a part or performing a functional validation on a rigid schedule and knowing the optimal moment for operations and lifecycle costs. With condition-based repairs, we can cut maintenance costs by 5-25% and optimize spare parts inventory by up to 30%.

Real-time monitoring can be achieved with connected sensors. Wireless and wired sensors (along with AI) can monitor for conditions and report to a centralized information system. We can use these sensors to check a variety of key parameters including:

- Heat Monitoring - Detects heat caused by insulation issues or conduction problem so you can act before discharge events or arc faults.

- Partial Discharge Monitoring - Partial discharge usually isn’t visible, but it destroys insulation over time, which will cause a full and destructive discharge.

- Circuit Monitoring - Measures power and power quality data, including harmonic disturbance in the wave forms and voltage transients (sags and swells) that can damage to sensitive equipment.

Using AI and machine learning, we can then use this data to detect patterns or anomalies signaling potential failure risks. For instance, a spike in pump vibration could prompt preemptive action. Over time, this data helps spot asset anomalies and predict equipment failures before they happen, boosting overall equipment efficiency and facility uptime. Detecting issues early prevents damage and can extend equipment life by up to 15%.

But implementing PdM isn’t without hurdles! We need high-quality, accessible data and seamless integration with existing systems. Misinterpreting data without domain knowledge can lead to flawed predictions. Defining the right parameters for failure prediction models is critical, and robust security measures are a must to protect sensitive production data. Fortunately, new solutions are making this process easier and scalable across facilities.

Workforce Gaps

The talent shortage in our industry is no secret. Embracing outsourcing may be the answer to expand the labor pipeline as demand for skilled labor outpaces supply. This is particularly true if the outsourcing partner has in-depth expertise working within these highly specialized and complex environments. Facilities management partners can help fill talent gaps in construction, operations, and maintenance, provide valuable tribal knowledge, and help ensure safety and quality.

With an experienced team, we can implement the right technologies and innovations required to enhance efficiency, cut costs, and maintain product quality and support technology roadmaps.

The demands are unique, and the stakes are high. We can’t afford to be the "cobbler with no shoes" when it comes to running today’s advanced fabs. It’s time to embrace technology and innovation where it matters most—on the fab floor and in the subfab. The future of the U.S. semiconductor industry depends on it.