Signal integrity saves lives with automotive radar

July 27, 2015

The market for advanced driver assistance systems (ADAS) of all types, from cameras, displays and of course radar and LiDAR is on a path to quadruplin...

The market for advanced driver assistance systems (ADAS) of all types, from cameras, displays and of course radar and LiDAR is on a path to quadrupling in size as we increase the safety of today’s vehicles, while working toward the fully autonomous vehicle.

With high volumes comes the need to ensure streamlined manufacturing so more safety related systems can be included – while minimizing costs to the consumers. This puts pressure on every aspect of design and materials, right down to the board material, especially for high-frequency radar, where signal integrity becomes a major concern.

Just to put a number on the market, IHS Inc. predicted last year that semiconductor revenue for ADAS systems of all types will reach $2.6 billion by 2020, which is four times that of 2010’s number of $643.8 million. According to Akhilesh Kona, analyst for automotive semiconductors at IHS, the revenue for the radar and LiDAR chip space will amount to $653 million in 2020, compared to $236 million in 2013, equivalent to a compound annual growth rate of 16 percent.

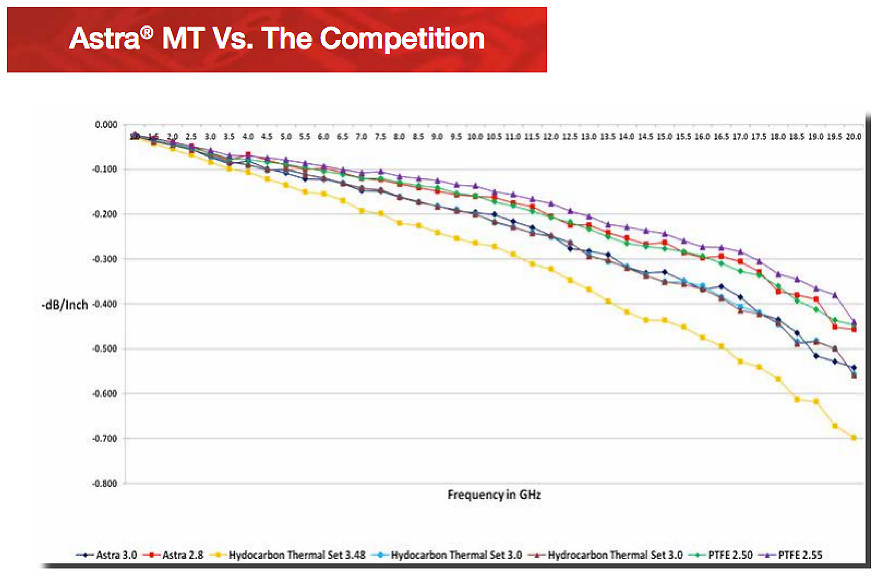

All these ICs need to go on a board, but not just any board. For most safety systems, FR-4 multilayer boards are sufficient. Their characteristics are well known, the processes are defined and they’re robust under high-speed drilling conditions. However, for high-frequency safety systems, such as radar at 77 GHz, FR-4 doesn’t make the cut as the signal-integrity issues loom too large even though the traces are typically short. Instead, low-dielectric-constant materials are required to ensure signal integrity and avoid compromising safety.

However, moving to more exotic materials such as PTFE can increase overall cost due to the special manufacturing processes required.

Figure 1: Signal integrity at higher frequencies is very dependent on material characteristics such as dielectric constant. Some materials perform better than others, but for high volume applications, cost is critical, and that’s where materials such as Astra MT really shine.

As volume increases, system manufacturers need to make sure that the ICs they pick not only have the performance needed for signal generation and detection, but that they’re matched to the right boards that will keep overall system costs down.

That’s what was so exciting about the demonstration at the International Microwave Symposium (IMS) 2015 event where we had an evaluation by RFbeam Microwave of Freescale Semiconductor’s millimeter-wave radar chipset on a board constructed using our Astra MT laminate materials.

The ultra-low-loss Astra MT dielectric materials are ideal for patch-antenna designs and RF front-end PCBs for 76 GHz to 81 GHz radar applications. They feature a dielectric constant (Dk) of 3.00 ±0.05, a dissipation factor (Df) of 0.0017 ±0.0005 and maintain excellent dielectric properties over a broad frequency and temperature range, per IPC-TM-650-2.5.5.5.

But what’s also key is that the material enables a higher yield in RF-hybrid PCB manufacturing, thereby reducing production costs and ensuring wider deployment of radar systems for automotive applications.

DFX Engineering was pretty excited too: they interviewed Isola’s Pat Sparks at the show. You can see the full interview here.

PS: Isola also demonstrated the reliable electrical performance in wide field-of-view radar applications for automotive systems.