3 Reasons Why the Automotive Industry Has Adopted Stepper Motors

October 21, 2025

Blog

Stepper motors are a type of electric brushless motor that divides a full rotation into equal steps, enabling precise control. These motors are characterized by their ability to control both speed and positioning, making them highly reliable and efficient in applications requiring fine movement control.

They operate by energizing coils in sequences, which produce incremental rotations of the motor's shaft. Traditionally, they have been used for accurate positioning and control in applications such as robotics and 3D printers, but they are increasingly being used in the automotive industry.

Electric Mobility Driving Demand

As the automotive world transitions rapidly toward electrification, the demand for stepper motors has skyrocketed. They play crucial roles in functions requiring high precision and control, from HVAC systems to advanced driver assistance systems (ADAS).

The migration toward electric vehicles (EVs) has led to a significant surge in the use of stepper motors. Tier-1 suppliers and OEMs are therefore particularly focused on integrating stepper motors into EVs.

EVs rely on electronic systems far more than their internal combustion engine counterparts. The need for precise control and reduced mechanical complexity means stepper motors offer an ideal solution for many critical functions.

3 Key Automotive Applications

1. HVAC control

Stepper motors play a key role in automotive climate control systems by driving HVAC actuators that manage airflow and temperature distribution. Their precision enables efficient thermal management, crucial for passenger comfort and energy savings in EVs.

Elsewhere in the thermal management system, stepper motors in electronic expansion valve (EXV) controls are used for refrigeration circuits, with the ability to regulate refrigerant flow precisely, which helps optimize cooling efficiency, extend battery life, and improve overall energy efficiency.

And finally, they are used to enable the opening and closing of flaps in the vehicle’s air ventilation systems, optimizing airflow into the cabin based on the climate control settings. Their use ensures energy efficiency and precision in maintaining cabin comfort.

2. Headlight adjustment

Stepper motors allow for precise headlight positioning and beam adjustment, ensuring optimal visibility without dazzling other drivers. Adaptive headlight systems in EVs increasingly rely on stepper motors to offer dynamic lighting responses based on real-time driving conditions.

3. HUD

By precisely adjusting the internal reflective structure of the HUD with a stepper motor, the projected image on the windshield can be controlled. This not only meets the diverse visual requirements of drivers but also enhances driving safety.

.jpg)

Image 1: A stepper motor precisely adjusts the HUD's internal reflective structure, optimizing the projected windshield image to meet drivers' visual needs and improve driving safety.

Automotive-Grade Stepper Motor Drivers

A driver for a stepper motor is an electronic component that converts pulse signals from the controller to “drive” the motor's step sequences, regulating the power and ensuring precise movement, speed, and direction for accurate positioning.

It is vital to select automotive-qualified drivers for stepper motors as they will likely be exposed to extreme temperatures, vibrations, water and dust ingress, and electrical noise. Automotive-grade drivers are rigorously tested for reliability, safety, and durability, ensuring optimal performance in these demanding conditions. They should also meet industry standards like AEC-Q100 to ensure enhanced protection and longevity in critical vehicle applications.

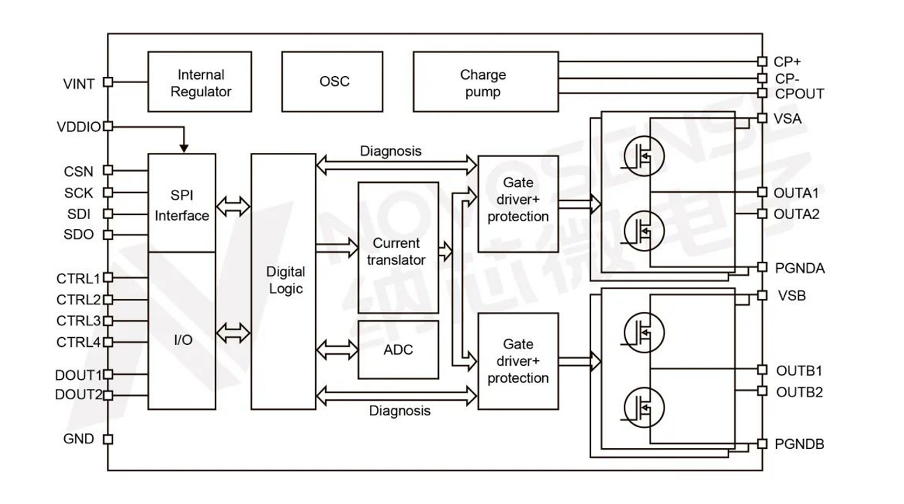

Figure 1: The automotive-grade NSD8381-Q1 features SPI, PWM frequency spread spectrum, sensorless stall detection, and temperature warning and shutdown.

The NOVOSENSE NSD8381-Q1 is an advanced automotive-grade programmable stepper motor driver designed to meet the increasing demands of EV applications like headlight adjustment, HVAC systems, and HUDs. It supports a wide operating voltage (4.5 V to 36 V) and offers up to 1.35 A current with 1/32 micro-stepping resolution. Its integrated SPI communication allows for flexible configuration, while the sensorless stall detection ensures real-time monitoring of motor conditions, helping avoid system failures. It also integrates advanced features like full-bridge and half-bridge motor control (fig. 2), offering unparalleled flexibility for managing complex automotive systems.

.png)

Figure 2: The NSD8381-Q1 can be configured flexibly to support various types of loads, as this application diagram of the NSD8381-Q1 driving a stepper motor and 2-DC motors illustrates.

The NSD830x-Q1 series of 40V multi-channel half-bridge drivers from NOVOSENSE is a versatile, multi-channel half-bridge driver designed for automotive HVAC, climate control, and other motor-driven applications. With their 40 V voltage rating and peak current capability of 1 A, they can drive multiple loads such as brushed DC motors, relays, and LEDs. The driver also supports adjustable PWM frequencies, allowing for precise control of motor speeds and soft start functionality in applications like mirror control and HVAC systems.

.png)

Figure 3: The NSD830x-Q1 not only offers an SPI interface and multi-channel drive mode but also features various additional functions to flexibly support a wide range of loads

Both the NSD8381-Q1 stepper motor driver and the NSD830x half-bridge driver complement each other in automotive systems. By leveraging their combined strengths, automotive designers can enhance system reliability, control, and energy efficiency in electrified vehicles.