The Advantages of Decoupling Hardware and Software in HMIs

July 09, 2025

Blog

A Human-Machine Interface—HMI for short—is a device that allows users to control industrial machines. Also known as panel PCs, HMIs have evolved from basic button-operated displays into sophisticated touch screens that often serve as a local hub for managing connected devices.

In this new role, HMI design has become critical to the market success of industrial equipment. A thoughtful HMI strategy not only enhances the user experience but also contributes to a consistent brand identity across different products. Furthermore, it can support scalability, with software enabling different feature tiers across a product family.

This article explores the requirements of modern panel PCs and outlines the advantages of a new modular approach. It focuses on the needs of mid-volume equipment manufacturers and explains how decoupling hardware from software can facilitate industrial machine development.

Limits of Traditional HMIs

Engineers face a range of challenges when designing HMIs. Custom hardware design and verification efforts can be surprisingly long and complex, often making the design of an HMI front end impractical, particularly for mid-volume manufacturers with limited engineering resources.

To simplify industrial machine development, many teams turn to panel PCs that combine display and computing functions in a single enclosure. These off-the-shelf systems offer convenience, being ready to mount into a machine. However, many come with significant trade-offs. Fixed hardware configurations and operating system (OS) limitations can hinder tiered product strategies and shorten product lifecycles.

Durability is a concern. Some panel PCs may not offer sufficient protection against dust, vibration, or moisture, making them unsuitable for use on the factory floor. The lack of certifications, such as UL or MET mark, may preclude use in certain applications. Additionally, limited interfaces and mounting options may force design compromises.

Software constraints are common as well. In tightly integrated systems, it can be difficult to update or reuse software across product lines, especially when the hardware cannot be easily swapped or upgraded.

Modularity as a Solution

A modular HMI platform offers a way around the limitations of conventional panel PCs. Built on a flexible combination of computing platform, display, and portable OS building blocks, such a platform can be readily adapted to specific product requirements, enabling faster development cycles, easier customization, and smoother upgrades.

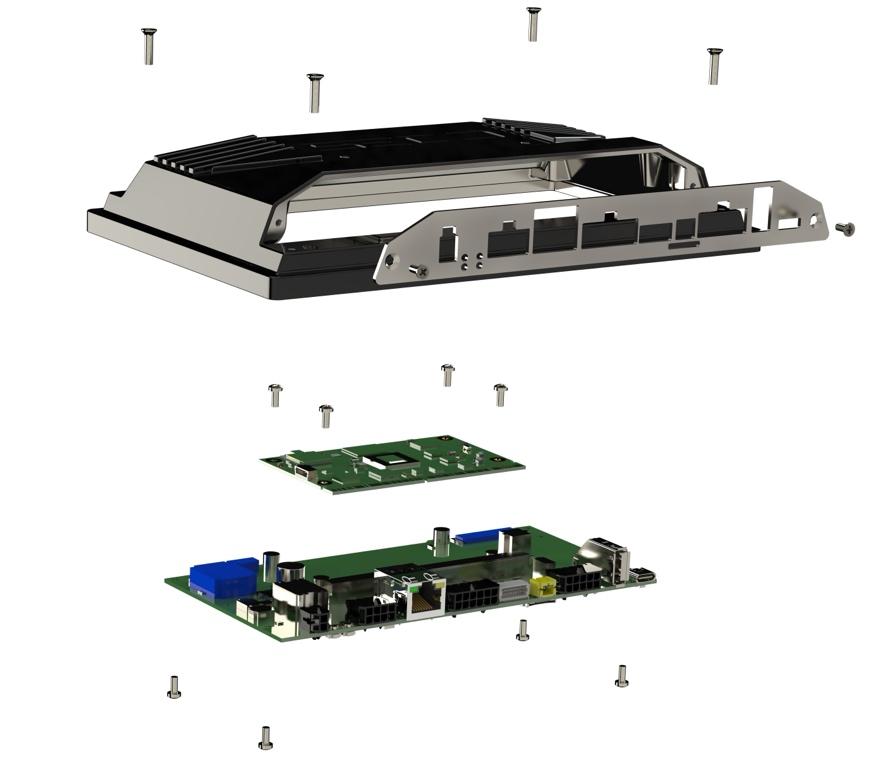

Figure 1. A modular HMI enables designers to choose the compute and display hardware that meets their needs while retaining the compact form factor of a panel PC.

The modular design centers on an embedded computing board known as a system-on-module (SoM). The SoM plugs into a carrier board that provides I/O and interfaces with the display. This architecture allows a single HMI platform to support a variety of computing platforms, as well as displays of various sizes and resolutions. The HMI vendor completes all design and certification updates, enabling equipment manufacturers to choose whichever combination suits them with minimal design effort.

SoMs typically use an industry-standard form factor like SMARC to ensure long-term scalability and vendor interoperability. If more computing power is needed down the line, a different SoM can be used without redesigning the entire HMI.

This flexibility also allows manufacturers to support a wide range of product variants using a common platform. For example, a low-power Arm-based module might be used in an entry-level model, while a high-end model could use a higher-performance x86 variant.

Integration into industrial machinery is also simplified. A modular system offers a consistent I/O layout across configurations, which streamlines mechanical design and simplifies cable routing and enclosure sealing. With multiple mounting options available—such as panel, flush, rear, or VESA—developers can fit the HMI into a wider range of equipment with fewer compromises.

Robust Software

One key advantage of a modular HMI platform is the ability to decouple software from hardware. In conventional systems, software is often tightly bound to specific hardware configurations, making reuse difficult and upgrades expensive. A modular approach breaks this dependency, allowing developers to support multiple product variants without maintaining separate software codebases.

To achieve this goal, HMI platforms can take advantage of architecture-agnostic software stacks that bring together operating systems, IoT middleware, communication protocols, and development tools. With this flexible framework in place, application code can be reused or ported across hardware—whether Arm or x86—with minimal changes.

The benefits go beyond development speed. A unified software environment improves maintainability, enhances security, and streamlines onboarding for development teams. It also supports long-term efficiency: once an application has been validated on one configuration, it can be deployed across other models in the product line without starting from scratch. With emerging cybersecurity regulations, such as the Radio Equipment Directive Delegated Act (RED-DA) on Cybersecurity (EN 18031) in Europe, a common codebase facilitates compliance across multiple processor platforms.

Modular HMIs in Practice

SECO’s Modular Vision platform illustrates how a modular HMI architecture can be applied in industrial environments. Clients can select from off-the-shelf HMIs offering selected Arm and x86 embedded computing platforms and three standard display sizes (7”, 10.1”, and 15.6”). The computing platform is implemented via a SECO SMARC SoM.

Figure 2: The Modular Vision 10.1 MX8M-Plus is a 10.1-inch HMI based on an NXP i.MX 8M Plus processor. Figure: SECO)

Key to minimizing software porting across processor platforms is SECO’s Clea OS, a Yocto-based Linux framework that incorporates key IoT data orchestration, remote device management, over-the-air (OTA) updates, cybersecurity, and DevOps technologies. To build software, only the target processor platform must be specified. No other adjustments are required.

This modular design helps reduce development effort and supports reuse across product lines. It allows relatively easy implementation of alternative processor-display combinations not provided off-the-shelf. Hardware variations can be introduced without modifying the software stack, and vice versa. As a result, engineering teams can respond more quickly to changing requirements while maintaining a unified platform strategy.

Conclusion

Modular HMI platforms address many of the limitations of traditional panel PCs. By decoupling hardware and software, they make it easier to scale performance, reuse code, and adapt to evolving requirements.

This approach reduces development effort, shortens time to market, and supports a unified strategy across product lines. As demands for connectivity and flexibility grow, modular architectures offer a practical foundation for long-term adaptability.

For more information, visit: usa.seco.com