The latest LED-based microscope illuminators improve inspection efficiency

December 18, 2015

Inspection microscopes are used in a wide range of industrial applications, from inspecting PCB solder joints and examining diamonds and other gemston...

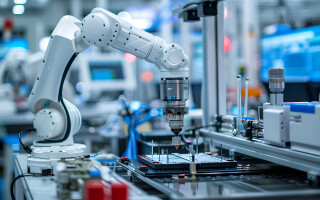

Inspection microscopes are used in a wide range of industrial applications, from inspecting PCB solder joints and examining diamonds and other gemstones, to analyzing medical devices in the lab and inspecting damage on fine industrial tools. Illuminator technology has changed drastically in recent years with the introduction of high-output LED bulbs and advanced lens optics. Most recently, illumination systems with built-in laser technology have revolutionized inspection microscope illumination by solving the common problem of locating specific microscopy targets. Overall, these innovations have brought benefits of brightness, energy efficiency, clarity, control, and ease of use to the field of inspection microscopy.

Initially, inspection microscopes were used with external illuminators comprised of halogen bulbs; these illuminators, however, weren’t bright enough and heated up considerably during use, which was damaging to some inspection subjects. Later, fluorescent lights were introduced, and external illuminators were designed to be ring-shaped rather than single point of light sources. However, fluorescent lights don’t meet the increased demands for brightness in many inspection microscope applications.

The next illuminators introduced to the market were fiber optic and LED-based. Fiber-optic illuminators, which channel a remote light source, are still used in high-end applications, and are effective and bright. But they’re considerably more expensive than other options. LED illuminators held promise, but early iterations used 40 or more standard 5 mm LEDs, which degrade over time, burn out quickly, and still don’t achieve the ideal brightness for many applications.

Engineers hampered by the limitations of previous inspection microscope illuminators relied on collimators and Fresnel optics to narrow and direct the lambertian spread of light from 16 high-output LEDs toward the center of the microscope’s stage to evenly illuminate the subject. Their ring light combines the energy efficiency and heat-free operation of LED lights with enough brightness to enhance clarity and visibility of inspection subjects.

In many cases, the product being inspected by a microscope is relatively large, while the inspection targets are very small and often repeated. For instance, take circuit boards solder joints. The circuit board may have 100 or more identical or very similar components, each soldered in place. While an inspector may be able to easily locate a certain point on the board based on macro observations, like distance from an edge or a large component, those macro observations often aren’t useful once the inspector is examining the board through a microscope’s reduced field of view.

Frustrated by this finicky process, Orled’s engineers realized that the task could be achieved by integrating laser pointers into the illuminator. This improves the ring light’s functionality and the overall ease of use of the inspection microscope. They implemented the update to the company’s high-output LED ring light, in the form of line lasers mounted on the ring light at 90 degrees from one another.

When activated, the two targeting lasers emit fans of light that create a bright crosshair pattern on the microscope stage that inspectors can use to center and identify microscopic subjects without moving the subject or pointing. It relies on collimators and Fresnel optics to narrow and direct the lambertian light spread from 16 high-output LEDs toward the center of the microscope’s stage. Introducing laser crosshairs into this innovative light source improves efficiency in locating inspection subjects to the list of benefits.

Marc Weissfloch is a mechanical engineer and product designer at Orled, based in Portland, Oregon.