Through Hole and Surface Mount Combination PCB Pads

April 18, 2023

Blog

Should you use through hole technology (THT) or surface mount devices (SMD) for your next design? While SMD opens a whole new world of miniature components and machine assembly, if you’re designing something for others to solder in kit form, THT can be more accessible.

What if you have a product and/or prototype that can be offered as a kit or as an assembly? My answer, the combo THT/SMD footprint!

THT, SMD, Why Not Both?

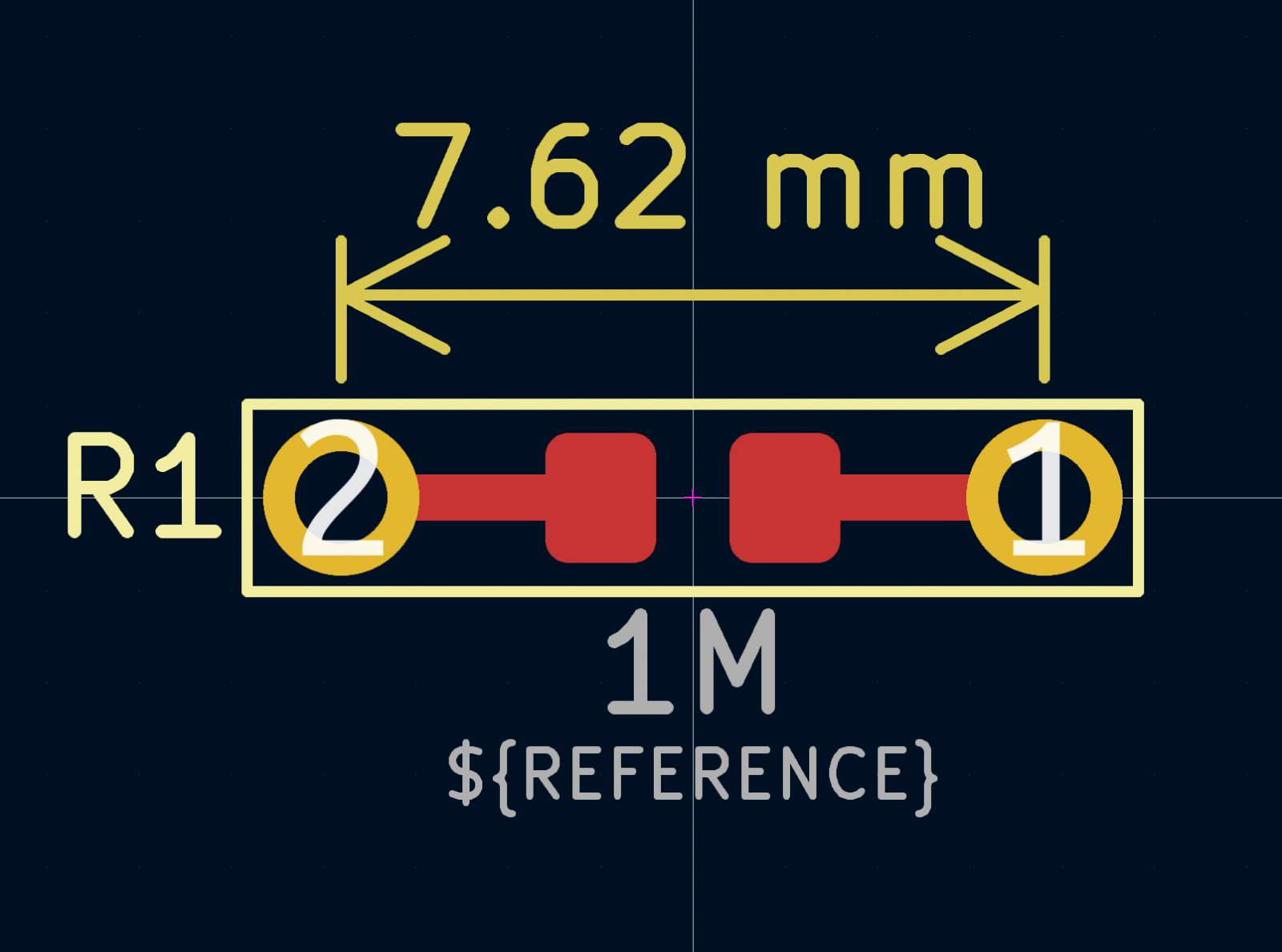

New "combo resistor" pad to allow the option of surface mount or through hole resistors.

— Jeremy Cook 🤖 (@JeremySCook) March 8, 2023

Unconventional, but seems it would work - typically populate one or the other. @kicad_pcb pic.twitter.com/Z83sxRFiyx

One of the chief advantages of SMD assembly is that the component footprint is typically much smaller than THT. In my case, I have been developing a capacitive foot pedal on a 100mm x 100mm PCB that requires only a Raspberry Pi Pico and three 1Mohm resistors. Space is therefore not a major concern, and resistors seem well suited for combining into a SMD/THT package.

For this job, I designed a custom footprint, which affixes the 0805 SMD resistor below where a THT component would sit. Alternatively, one can leave off the SMD resistor if a THT component is used. In addition to giving you assembly options, it makes the connection extremely easy to test, and a THT component could even be added on top of the existing SMD resistor at a later date.

.jpg)

Caption: Combo pads also allow for more compact (and drab) SMD resistors

Image Credit: Jeremy Cook

While the early 2020s microprocessor shortages are (hopefully) coming to a close, one could also see different microcontroller formats being nested for design agility purposes. While not a component flexibility feature per se, the Raspberry Pi Pico footprint that I used also features SMD and THT pads for attachment, again, giving you soldering options.

Alternatively, you could arrange your components side-by-side and connect them in parallel, leaving what’s not needed unpopulated. This would ,however, be even less space efficient on your board.

Reasons Not to Combine

Image Credit: Jeremy Cook

While this combo resistor appears that it will work in my application, it’s probably healthy to step back and consider why this isn’t done more often. Space constraints are the obvious issue, and the fact that most electronics don’t come as kits, or even use that many THT parts, doesn’t help its case either.

Solder can also leak down into the THT pad when attaching the SMD component, making this process slightly more difficult. This is likely not a dealbreaker, and something that would be trivial for an individual that has practice with soldering SMDs.

Finally, manufacturing at scale typically demands a set process, not a bunch of options. Give your assembly operation a few alternative procedures to follow (whether in your facility, or at the customer/assembler) and the potential complications increase exponentially.

SMD, THT Design Toolbox

At the end of the day, there are only so many reasons to make a combo part, though it’s an interesting idea that’s worked for me in my very preliminary testing. For prototyping, kits, and perhaps other purposes, you never know when this technique might come in handy!

.JPG)