DLP cinema technology shows up in industrial, automotive, and other markets

January 08, 2015

Have you seen a movie in a theatre lately? If so, it's likely that some of the following technologies were involved: a digital screen using Texas Inst...

Have you seen a movie in a theatre lately? If so, it’s likely that some of the following technologies were involved: a digital screen using Texas Instruments DLP Cinema technology, an IMAX digital theatre, 3D, and high-frame-rate playback. All of these entertainment innovations are enabled by DLP products. Today, more than eight of ten digital theatres worldwide use DLP Cinema technology, which has become a popular industry standard for many reasons, but three factors stand out: speed, reliability, and light efficiency.

The fast switching speed of the digital micromirror device (DMD), or DLP chip allows the DMD’s image content to change in fractions of a second, resulting in a smooth, high-resolution 3D viewing experience. It also allows for a high frame rate, up to 60 frames per second (fps), designed for fluid motion of fast, action-packed visuals.

The DLP chip has proven to be reliable with more than 40 million chips sold and quintillions of pixel cycles tested since the technology’s inception. DLP Cinema projectors run for over 900,000 hours per day, every day. The high light efficiency of DLP’s optical architecture is demonstrated by a fill factor of up to 96 percent, even at a high resolution, and native full-on, full-off contrast ratios of more than 2000:1.

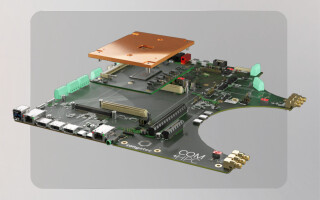

Personal electronics markets, like industrial, medical, and automotive are starting to incorporate DLP. Since a series of launches in 2012, users have seen a wide range of applications. Products are classified under display and advanced light control applications. Display applications incorporate a product that uses projection technology to display information or play video content. Advanced light control applications are products that use programmable optical sensing or control.

Near-infrared (NIR) spectrometers enabled by DLP technology consist of test and measurement equipment that use the NIR region of the electromagnetic spectrum to identify a solid or liquid’s chemical composition. These devices are used in factories, pharmaceuticals, and agronomy. For example, they’re used in a factory environment to verify a raw material’s purity that will be used in a manufacturing process.

To measure the spectral signature of a solid or liquid, the measurement device must capture the light transmittance for a given wavelength range. Some traditional spectrometers use a linear array detector in conjunction with a grating to capture the NIR spectral signature. In contrast, the DLP-equipped NIR spectrometer captures the NIR spectral signature using a single detector. A DMD’s 40-kHz switching speed lets it quickly scan the 700 nm to 2500 nm wavelength range on to the detector. In addition, a DMD’s high light efficiency lets it capture most of the light being sampled, resulting in a high signal to noise ratio, 30,000:1. This optical architectural difference lowers the detector’s cost, decreases the measurement unit’s size, and provides fast data acquisition to attain the spectral signature.

Another application enabled by DLP technology is the automotive head-up display (HUD), which lets drivers see relevant information without having to look away from the road. Traditional automotive HUDs use an LCD screen with a field of view of up to 6 degrees. Recent HUD systems leverage the same DLP technology that’s used in digital theatres. By incorporating DLP technology with a picture generation unit, drivers can experience a field of view of up to 12 degrees. Read a technical white paper covering technical aspects of the automotive DLP head up display.

Augmented reality near-eye display (NED) is another application based on DLP Cinema technology. It allows someone to have a display on-demand that supplements your field of view with information presented by the NED device. Solutions for this market are starting to pop up in industrial and personal electronics applications.

An augmented reality NED incorporating a DLP chipset can include a high performance display that supports high contrast, low latency, and high fill factor. High contrast lets a user minimize the transition of the background of the real environment against the transparent image that’s shown on the display. Low latency allows the minimum lag between the source information that is processed and the information on the display itself. High fill factor minimizes pixelization of the display delivering a smooth image quality. There’s a white paper on this technology too.

Juan Alvarez is the director of communications supporting Texas Instruments’ DLP products and is responsible for communications strategy and execution. He has a BS from Universidad EAFIT (Medellin, Colombia) and an MBA from SMU (Dallas, Texas).