The Semi-Custom Sweet Spot: Proven Solutions Without Starting from Scratch

September 23, 2025

Blog

Engineering teams must often choose between COTS systems that may not entirely meet requirements and fully custom designs that are more than they need. This article outlines how semi-custom is the solution. By combining proven components with specific customizations, semi-custom solutions reduce execution risk, accelerate delivery, streamline compliance-readiness, and provide long-term lifecycle support.

If you’ve ever been under pressure to find a rugged computing solution—a tight product deadline, regulatory requirements, inflexible specs, and leadership asking for guarantees—you know what it feels like to need one quickly, confidently, and without creating new risks.

Common solutions like commercial-off-the-shelf or custom are not always ideal. COTS often falls short of all needed features, and full custom can be slow, costly, and risky. If the wrong product is selected, it can place both the process and the decision-maker under scrutiny. So, you must find a solution that satisfies all your stakeholders. That’s when semi-custom becomes the clear alternative hiding in plain sight. While not always the obvious answer, semi-custom could be the most practical solution.

Some people may hear “semi-custom” and think it’s not a feasible option, but I can say from experience that it often is a great choice. It’s a strategy that blends proven building blocks with limited customization. You can work from a solid foundation and adapt it to optimally fit your current application requirements. There’s no need to start from scratch with semi-custom.

Semi-custom is an approach that helps you meet high standards without added complexity. One that reduces risk in ways that ripple far beyond the technical design. If you’ve ever led a project where performance, timeline, and confidence all mattered equally, then semi-custom might be the alternative you didn’t know you had.

This is what you need to know about choosing semi-custom and how it can serve as the sweet spot for your rugged computing solution.

Why Semi-Custom Is the Sweet Spot

Semi-custom is the bridge between rigidity and reinvention. It’s a smart strategic choice because it lowers uncertainty and delivers exact-fit performance while preserving budget and schedule. At the core of every semi-custom solution is a set of reliable technical strengths that puts cross-functional teams in a position to succeed. These strengths place semi-custom squarely in the sweet spot between basic COTS and completely custom.

- Risk Reduction at Every Stage: Semi-custom solutions rely on existing, validated designs as a starting point, which means fewer unknowns during development. Reusing proven I/O circuits, subassemblies, and enclosures minimizes the chances of technical surprises, design flaws, or late-stage failures. With lower risk, you get smoother integration, fewer delays, and more predictable outcomes.

- Shorter Development Timelines: Speed matters when tied to market readiness, contract deadlines, or urgent infrastructure rollouts. Because semi-custom leverages existing technology, much of the design and test work is already complete. That compresses development cycles. So, from your initial contact to deployment, you get accelerated schedules that jump over time-consuming hurdles.

- Quick and Exact: One of the best qualities is that you don’t have to trade specificity for speed. You get both. Semi-custom enables precise tailoring. Whether it’s tweaking the I/O mix, board footprint, or thermal profile, you can quickly get what you need without the full custom time and cost overhead.

- Streamlined Certification and Compliance Readiness: Integrated certifications remove back-end bottlenecks during the product release process. Because the base technologies in a semi-custom design have already passed reviews and testing, your compliance readiness is simplified.

- Long-Term Lifecycle Support: With semi-custom, supply chain, and revision control can be planned proactively. You can lock in extended availability, standardized firmware, and long-term support. You sidestep the obsolescence pitfalls and reactive redesigns made necessary when COTS products reach end-of-life.

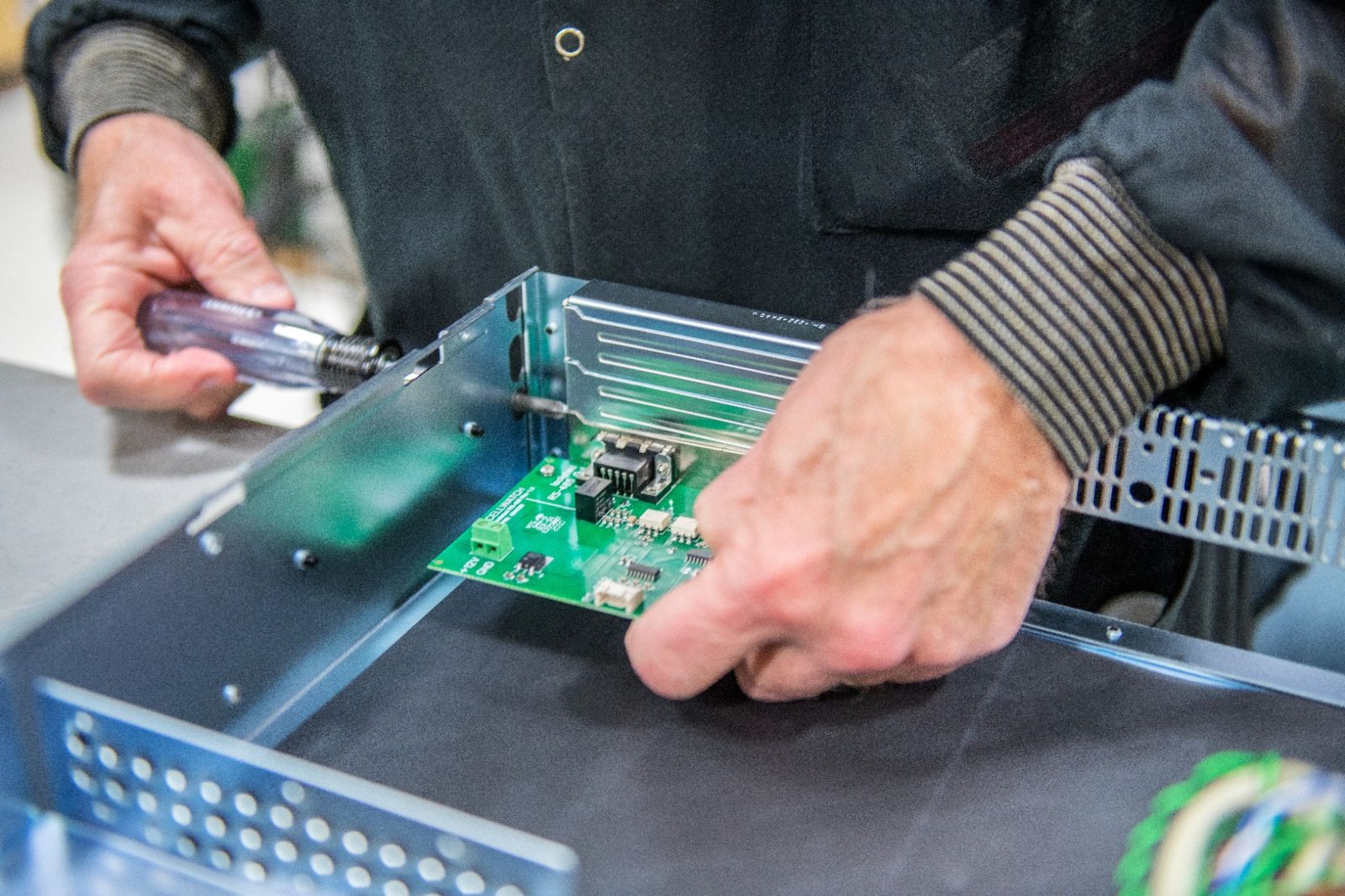

Image 1: An engineer measuring and modeling a circuit board design, illustrating how semi-custom solutions blend proven platforms with specific customizations. (Sealevel Systems)

Those strengths matter for anyone responsible for technology decisions. Together, they create confidence, not just in the product, the process, or the partner, but in your own judgment. Choosing semi-custom becomes less about risk and more about strategic decision-making.

Making the Semi-Custom Call

Behind every technical decision is a person or team carrying the weight of expectations: fulfill the specs, stay on schedule, prevent surprises. You may have to navigate external pressures while also dealing with internal second-guessing. There are real emotional undercurrents in decision-making that come with making a high-impact call. I understand; I’ve seen it.

However, semi-custom replaces uncertainty with clarity. You’re not betting on an unproven system. You’re adapting known tools into a tailored application with guidance from industry experts who’ve done it many times before.

Image 2: Technician mounting a circuit board into an enclosure, which is a practical step in the semi-custom approach that reuses existing components to shorten development cycles. (Sealevel Systems)

The confidence that brings can’t be overstated. Executives notice when a project goes smoothly. Procurement officers appreciate predictable pricing and lead times. Program managers welcome fewer integration surprises. Having a clear path forward—built on established technology and delivered through a trusted system—can ease any doubts leaders may have.

When the tailored system arrives fully functional as expected, it confirms you made a smart call and influences how the entire project is perceived and supported. In this way, semi-custom becomes more than a single accomplishment; it becomes an organizational win with measurable results.

Here’s what that looks like in practice.

Solving Real-World Problems

Most people don’t realize how much semi-custom products already support the systems they rely on. Behind public safety infrastructure, industrial automation platforms, and critical energy controls, you’ll often find semi-custom solutions that started from existing building blocks and creative engineering.

I recall one energy customer who needed a rugged computing solution that met tight environmental and I/O specs. The answer was an adapted carrier board paired with established COM Express technology inside a weather-resistant enclosure. Because it was built on proven components, there was no lengthy design cycle, so the customer met their challenging product introduction schedule.

In public safety, a project supporting 911 dispatch communications—where lives can hinge on system performance—required a unique mix of digital and audio interfaces, all within a tightly constrained footprint. The OEM partnered with our team to adapt proven I/O circuits and enclosure know-how to design a system that supports emergency response infrastructure. Communities nationwide ultimately felt the impact through more reliable communication, faster response times, and better outcomes.

What both of those examples have in common is that engineers didn’t have to build something brand new or take an unnecessary risk. They only needed a smarter path forward. Semi-custom gave them that path.

AS9100D Certification Provides Assurances

When a semi-custom product is developed within an AS9100D-certified framework, it means documentation, traceability, supplier oversight, and quality assurance are included at the start. For those of you in the aerospace and defense sectors, this level of rigor is a must-have.

Customers in other industries will also benefit from the quality AS9100D processes deliver. Under this system, you can trust that semi-custom designs are manufactured and tested to the same exacting standards as COTS products.

Finding the Sweet Spot

When you’re feeling pressure—facing deadlines, scrutiny, and high expectations—it’s comforting to know there’s a way forward. By going with a semi-custom system, you’re implementing a low-risk, reliable strategy for success. It allows your organization to move faster without compromising quality.

Semi-custom provides not just a technical win, but a reputational one, proof that you can steer complexity with confidence. All it takes is a clear understanding of the problem you’re trying to solve.

So, if you’re facing a challenge that off-the-shelf can’t handle and full custom feels like too much, then you might be closer to the semi-custom sweet spot than you realize.

Earle Foster, Senior Vice President of Sales at Sealevel Systems, Inc., leads customer engagement and strategic solution development. He is known for championing the semi-custom approach, balancing precision engineering with practical delivery to help customers meet technical and organizational goals with confidence.

For more information, visit: https://www.sealevel.com

Check out some of our recent podcasts featuring Sealevel Systems: